A Focus on Liquid Handling

July 2023

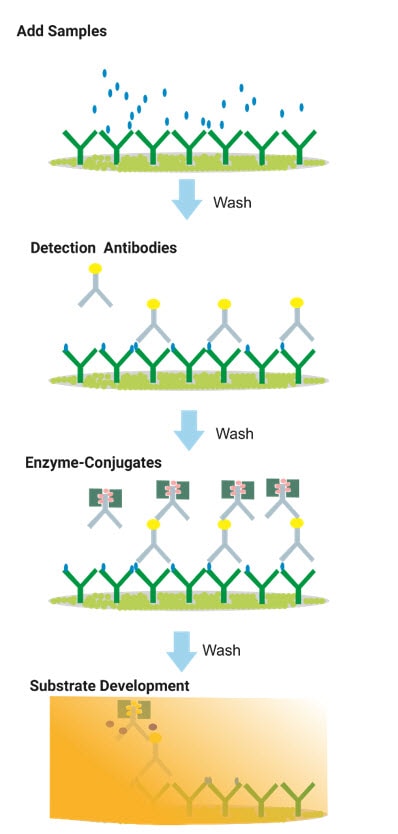

In this edition of TekTalk, we’ve compiled resources that demonstrate the utility of an instrument with both washing and dispensing capabilities within the context of widely used applications. Many microplate-based assays require a wash step that involves the aspiration of the fluid from the microplate well, followed by a fluid dispense as a replacement. Complete removal or replacement of the original fluid often requires multiple iterations or cycles of aspiration and dispense. After the final aspiration of a wash protocol is completed, often the next step in the assay protocol is the addition of a specific reagent. For example, ELISA reactions are antibody-based reactions that use a series of binding reactions to quantify specific analytes. After each binding step, unbound material is first removed by washing with a non-reactive buffer and the next reagent is added (Figure 1). Likewise, the fixation and staining of cells prior to fluorescence microscopy involves the addition of several reagents in succession with intervening wash steps to remove unreacted reagents. These labor-intensive procedures can be efficiently automated using instrumentation that has the capability to both wash and dispense reagents on a single hardware platform; such configurability saves both time and valuable lab space. Recognizing these advantages, Agilent BioTek offers automated liquid handlers that support washing and reagent dispensing within a single flexible instrument.

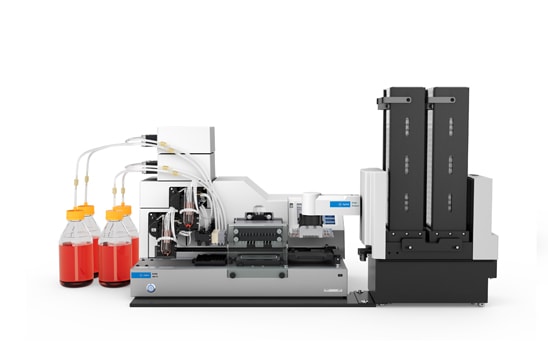

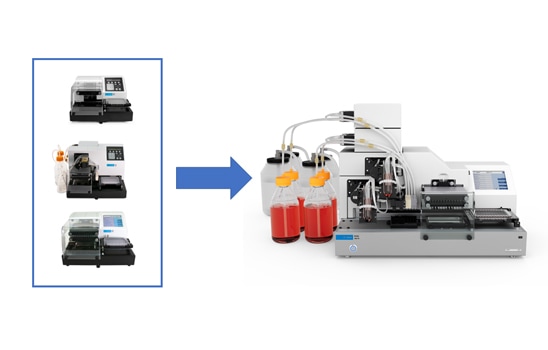

The Agilent BioTek washer dispenser is a modular system that is fully programmable from either its built-in touch screen or from Agilent BioTek Liquid Handling Control (LHC) software on an attached PC. The 406 FX is an automated microplate processor that can perform microplate washing steps in 96-, 384-, and 1536-well microplates for standard wash routines and cell-based assay wash processes. An internal buffer-switching valve allows the selection of up to four different wash buffers without changing bottles, and a built-in sonicator provides automated cleaning of the dispense manifold. The 406 FX can have up to six different reagent dispensers, including two separate peristaltic pumps that are capable of dispensing from 1 to 3,000 μL. Cassettes sizes (1, 5, and 10 μL) provide accuracy at different dispense volumes while minimizing priming volume. The 406 FX can also be configured with up to two dual syringe modules, each fitted with two independent syringe pump dispensers that are capable of dispensing from 5 to 3,000 μL. The 406 FX offers plate shaking at three different speeds and is compatible with the Agilent BioTek BioStack microplate stacker and Agilent BenchCel microplate handler, along with third-party automation systems.

In this edition of TekTalk, we’ve compiled resources that demonstrate the utility of an instrument with both washing and dispensing capabilities within the context of widely used applications. Additionally, we share some tips for achieving the best results with your combination automated liquid handling workflows.

Featured Applications

Automated Cell Fixing and Antibody Staining in Microplates

Fluorescence microscopy has traditionally been performed on microscope slides, but there is a growing trend towards the use of 96- and 384-well microplates, as this allows greater number of samples to be easily processed and automated, consistent with high-content analysis (HCA). This application note describes the use of the Agilent BioTek 406 FX washer dispenser to automate the fixing and staining processes typically used before fluorescence imaging.

Automated ELISA Liquid Handling Using the Agilent BioTek 406 FX Washer Dispenser

With a typical ELISA protocol, repeated cycles of microplate washing, reagent addition, and incubation are executed to add specific reagents and to remove unbound material before data collection. When performed manually, this process requires a technician to manage timing and be available to move plates between the washer and multiple dispensers.

Featured Product

BioTek 406 FX Washer Dispenser

The Agilent BioTek 406 FX washer dispenser is a compact instrument offering fast, full plate washing along with up to six reagent dispensers. The Dual-Action manifold optimizes washing for a variety of cell types, in addition to biomagnetic protocols in plate configurations ranging from 96- to 1536-well. The non-contact plate dispensing capabilities offer maximum flexibility, including up to four syringe pumps and two peristaltic pump dispensers that enable rapid dispensing of reagents, cells and other precious reagents. Plate access from either the left or the right side of the instrument makes it automation friendly.

Tek Tips

Best practices for not disrupting cell monolayers:

When used correctly, automating liquid handling steps for cell-based assay can increase throughput and reliability. However, the use of fluid dispensing or aspiration steps that are inappropriate for the conditions (e.g., a dispense rate that is too rapid) can cause a portion of the cell layer to be either washed off or folded over onto adjacent cells. The 406 FX washer dispenser fluidics are designed to allow for slow fluid rates, to avoid these potential problems while retaining dispense accuracy. The dispense tips are also angled vertically, to dispense toward the side of the well rather than directly onto the cell monolayer.

An additional important consideration is the column of fluid already present in the well, which can help prevent the disruption of cells in the well. The fluid column serves as a mechanical “shield” between the fluid jet delivered to the well and the cells on the bottom. The greater the fluid column (i.e., larger the volume), the more effective the shielding against fluid-induced cell damage. The aspiration height parameter can be used to modulate the fluid column between wash cycles. By using a height parameter that keeps the aspiration tube off the bottom of the well, residual fluid can intentionally be left in the wells. The elevated aspiration height serves a second purpose—positioning the aspiration tubes close to the cell layer for an extended period is harmful to the cell monolayer. A small yet strong vortex occurs near the aspiration tube that can damage fixed or live cells. The higher aspiration height increases the distance between the tube and the cell monolayer and provides some protection. Also, the 406 FX is configured with programmable aspiration rates that enable very rapid aspiration dive rates that minimize the exposure of cells to this deleterious force.

Optimizing settings for ELISA assays:

BioTek Agilent washer dispensers such as the 406 FX have preloaded default parameters that will readily perform the wash for most ELISA assays. However, differences in plate geometries, assay subtleties, and different buffer constituents may necessitate that some parameters be optimized for the best washing performance. The 406 FX has several different parameters that can be varied for both aspiration and dispense. For example, the horizontal position and vertical height of the dispense tubes can be altered. The manifold has angled dispense tubes, and by changing the dispense X-axis parameter, the dispense tube can be shifted toward one side of the well. Different plate heights can be accommodated by altering the Z-axis setting.

Similar parameters are available for the aspiration tubes as well. While the default position is the center of the well, several plate types require aspiration from the well edge for more effective aspiration. Likewise, differences in the physical height of the microplate bottom require a different aspiration Z-height setting. To minimize the buffer residual, the aspiration tubes need to be as close to the bottom as possible, without touching the well. The aspiration rate can also be changed from very gentle to aggressive, depending on the nature of the assay.

Once the wash parameters have been optimized, there are two critical items that need to be addressed. First, it is necessary for the wash programming to follow the assay kit instructions. It is critical that the correct number of wash cycles, dispense volume, soak time, and shaking (if required) are correctly programmed. The wash parameter instructions for assay kits have been optimized by the kit manufacturer. Immediately before the run, it is important to confirm that the washer supply and waste bottles have been attached correctly. While the supply container is not pressurized, the waste bottle is under vacuum and the top needs to be seated correctly and the tubing connected. Fluid flow sensors would alert the user, but a little bit of care can save time. Second, the washer must be primed with the appropriate buffer. This step removes residual fluids and air and replaces them with the appropriate buffer fluid. Failure to do so will result in either insufficient wash buffer or a dispense with an incorrect solution.

Resources

Visual Abstracts

Visual abstracts provide an animated, visual representation of the assay.

- Automated Cell Fixing, Staining, and Immunofluorescence in Microplates

- Automated Reagent Addition and Washing of ELISpot Microplates

- Automated Reagent Addition and Washing of Magnetic Bead Assays

- Automated ELISA Liquid Handing with the Agilent BioTek 406 FX Washer Dispenser

- Automation of Cell-Based Drug-Absorption Assays

- Automated Washing and Reagent Dispensing for Cell-Based Assays With Verification of Cell Retention

Video

Agilent BioTek 406 FX Washer Dispenser

The Agilent BioTek 406 FX washer dispenser is a compact instrument offering fast, full plate washing along with up to six reagent dispensers. The 406 FX capabilities include washing and dispensing for standard assays, plus biomagnetic separation and vacuum filtration protocols.

Webinar

Agilent BioTek 406 FX Microplate Washer Dispenser: Technology-Driven Application Diversity and Workflow Efficiency

Wednesday, July 19, 2023 | 12:00 PM EDT

Introducing the new Agilent BioTek 406 FX microplate washer dispenser. Built on decades of innovation and success, the 406 FX is the latest advancement in microplate washing and dispensing. The 406 FX integrates parallel peristaltic and syringe pump dispensing with microplate assay washing within a singular platform. The compact design of the 406 FX delivers fast, full-plate washing along with six reagent dispensers. From basic ELISA to sensitive cell washing, to biomagnetic bead washing, the 406 FX offers modules to address a myriad of assay requirements and workflows.

The automated microplate dispensers perform across a range of volumes offering simple, repeatable, and precise liquid delivery. Modular peristaltic and syringe pump dispensers help to meet varied liquid handling requirements, catering to the broadest spectrum of assay workflow requirements. This multidisciplinary tool enables researchers to drive a diverse spectrum of applications while maintaining workflow efficiency.

In this webinar, you will learn about:

- The technological innovation behind the 406 FX platform

- A range of workflows supported by the unique capabilities of the system

Promotions

Extend Your Throughput with This Agilent BioTek 406 FX and BioStack Promotion

Purchase the new Agilent BioTek 406 FX washer dispenser and get a compatible Agilent BioTek BioStack microplate stacker at 40% off list price.

Get 30% off a new Agilent BioTek 406 FX

Current owners of Agilent BioTek EL406 washer dispenser, 405 TS, 405 LS, and ELx405 Select washers are eligible for a 30% promotional discount on the all-new Agilent BioTek 406 FX washer dispenser and optional dispense modules.

Peri-pump Cassettes now available via e-commerce on Agilent.com

Now it’s easier than ever to order replacement cassettes for your Agilent BioTek dispenser equipped with one or more peristaltic pumps. Simply order your replacement cassettes from the several volume and tip type options available on Agilent.com.

Agilent BioTek cassettes are validated and compatible with Agilent BioTek 406 FX, MultiFlo FX, MultiFlo, and EL406.

See our helpful How-to videos to guide you through the time-saving features on the Agilent Online Store.

If you don’t already have an Agilent.com account, you can create one using this link.

Note that E-Commerce is not available in all countries.