Agilent Corporate Citizenship Report 2012

DMA EN

DISCLOSURE ON MANAGEMENT APPROACH EN

Agilent is committed to conducting its business in an ethical, socially responsible and environmentally sustainable manner by reporting performance and ensuring that production and operations meet or exceed relevant environmental legislation and regulations. We operate under a companywide environmental, health and safety management system (EHSMS) that applies to our design, development, manufacturing, distribution and sales and service operations worldwide. Agilent has demonstrated its effectiveness in managing environmental impact by maintaining an ISO 14001 registration of our Environmental Health and Safety Management System (EHSMS). EHSMS is a tool to drive continual improvement in environmental performance and pursuit of sustainability. We expect our suppliers to adhere to the same standard of environmental and social responsibility that we maintain, and our Supplier Environmental and Social Responsibility Code of Conduct requires suppliers to adopt sound environmental, health and safety management practices.

Agilent Supplier Code of Conduct

Agilent is committed to designing, manufacturing and distributing environmentally responsible products. Environmental aspects are considered in the design, manufacture, distribution, use, obsolescence, disposal, recovery and reuse of Agilent products. Our aim is to minimize environmental impact of our products and operations by conforming to applicable regulations. Agilent has developed an Environmental Compliance Framework to sustain and facilitate compliant product design, development, production, refurbishment and support. When a customer no longer requires an Agilent product, we have implemented several options for reuse, remanufacture or take-back based on the product type and customer location to ensure the product is properly managed. Additional information on our environmental and social performance may be found at Agilent’s Commitment to Environment and Social Responsibility.

Agilent recognizes ISO 26000 as a reference document that provides guidance on social responsibility. Agilent aligns with ISO 26000 standards as part of our social responsibility practices. As such, Agilent’s environmental policies, programs and procedures align with ISO Core subjects: Environment 6.5 and Organizational Governance 6.2

EN1

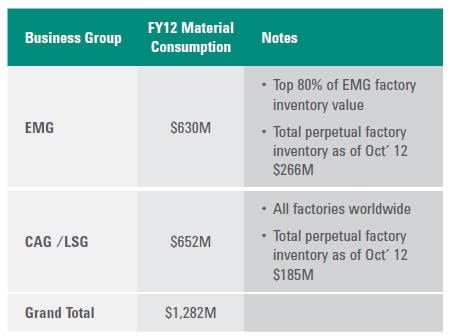

MATERIAL USED BY WEIGHT OR VOLUME

Currently we are unable to report material used by weight or volume; we expect to report this information in 2014. We will report cost of material consumption until we are able to report material usage by weight or volume.

EN2

PERCENTAGE OF MATERIALS USED THAT ARE RECYCLED INPUT MATERIAL

We do not currently report on this, as we lack automated reports for gathering the data; we expect to be able to report in 2014.

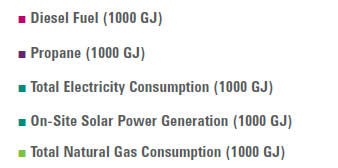

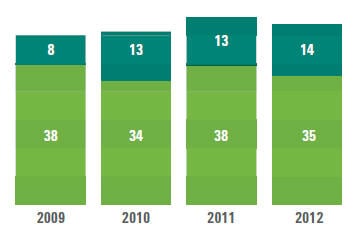

EN3

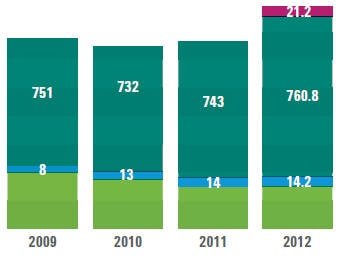

DIRECT ENERGY CONSUMPTION BY PRIMARY ENERGY SOURCE

(The data provided for energy and water has been attested by TruCost)

Worldwide energy consumption 20121

|

|

Notes: 1 US Energy Information Agency International Electricity Emissions Factor by Country, 1999-2002 were utilized for all non-U.S. facilities. 2012 Defra (UK Department of Environment, Food and Rural Affairs) factors were used to calculate emissions from stationary fuel consumption.

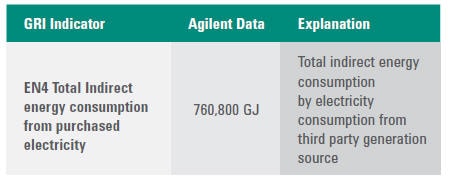

EN4 INDIRECT ENERGY CONSUMPTION BY PRIMARY SOURCE

1 For FY12data—EPA eGRID2012 Version 1.0 included 2009 emissions factors for CO2, CH4 and N20 used to calculate CO2 equivalent emissions from electricity consumption for U.S. facilities.

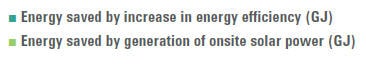

EN5 ENERGY SAVED DUE TO CONSERVATION AND EFFICIENCY IMPROVEMENTS

EN6 INITIATIVES TO PROVIDE ENERGY-EFFICIENT OR RENEWABLE ENERGY BASED PRODUCTS AND SERVICES, AND REDUCTIONS IN ENERGY REQUIREMENTS AS A RESULT OF THESE INITIATIVES

Agilent has worked on assessing energy efficiency of several types of products by using customer base metrics. By identifying energy-using features, we are able to increase energy efficiency of our products. During the past several years, Agilent has moved toward product energy efficiency in several product lines. Most of the energy savings are due to four key factors:

- The increased type and volume of tests that can be conducted, thus increasing tests per watt.

- Enhanced existing product features, thus bringing more measurement capabilities to the same product footprint.

- Increased offering of handheld products.

- Our design focus on measurement speed and accuracy, along with more advanced equipment, results in more measurement per watt-hour.

Agilent’s concentration on handheld and portable instruments places a focus on energy efficiency:

- Next-generation products are using key new technology that greatly improves performance per watt of power supply.

- Portable products put significant design efforts into power management to achieve power, heat and battery life targets.

- Industry and regulatory requirements on the power supplies for our portable products have also increased power supply efficiency.

EN7 INITIATIVES TO REDUCE INDIRECT ENERGY CONSUMPTION AND REDUCTIONS ACHIEVED

Agilent has a broad spectrum of initiatives ranging from capital spending for energy conservation projects and solar power to operational practices and employee action. For example, prior to delivery to employees, our IT service provider configures PCs and laptops with fully enabled, energy-saving settings. Operationally, we conserve energy by closely managing office heating/cooling and lighting, developing energy-efficient building design and operating standards and sharing best practices among sites. We also have a corporate energy conservation manager on staff and dedicated staff from our facilities maintenance company, whose primary role is to support the site facilities staff in identifying, implementing, and validating energy-saving opportunities.

We completed several energy-conservation infrastructure projects as well as operational improvements in 2012. Our net energy conservation for FY12 (for sites included in this report) was 4 percent (using FY11 total energy spend as a baseline).

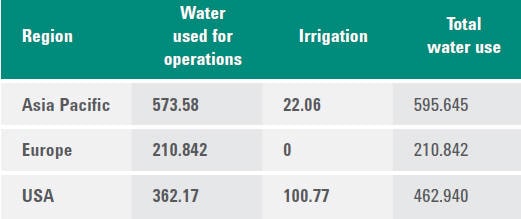

EN8 TOTAL WATER WITHDRAWAL BY SOURCE

- Total volume of water from water utilities (1000 m3) = 1269.427

- No wastewater from other organizations

- Water withdrawn from water utilities per region

◦ (1000 m3):

◦ Asia Pacific - 595.645

◦ Europe - 210.842

◦ USA - 462.940

Most of our manufacturing sites’ water comes directly from the city water supply. However, the following sites draw some water from the local aquifer: Manesar, India; Torino, Italy; Hachioji, Japan; Santa Rosa, U.S.

EN10

PERCENTAGE AND TOTAL VOLUME OF WATER RECYCLED

AND REUSED

The only site that currently uses recycled water is Santa

Rosa, U.S., which has an onsite wastewater treatment

facility. During the reporting period, the Santa Rosa site

recycled 62.66 (1000m3) water, or 38 percent of the total

annual consumption of the site. The Singapore site purchases “NEWater,” which is reclaimed water

produced by the local water board. It consists of treated

wastewater that has gone through water-treatment

processes including purification and UV technology.

EN11

LOCATION AND SIZE OF LAND OWNED, LEASED, MANAGED

IN, OR ADJACENT TO, PROTECTED AREAS AND AREAS OF

HIGH BIODIVERSITY VALUE OUTSIDE PROTECTED AREAS.

Not applicable. Agilent manufacturing sites are not

located in protected areas or areas of high biodiversity

value.

EN12

DESCRIPTION OF SIGNIFICANT IMPACTS OF ACTIVITIES,

PRODUCTS, AND SERVICES ON BIODIVERSITY IN PROTECTED

AREAS AND AREAS OF HIGH BIODIVERSITY VALUE OUTSIDE

PROTECTED AREAS.

Not applicable. Agilent manufacturing sites are

not located in protected areas or areas of high

biodiversity value.

EN13

HABITATS PROTECTED OR RESTORED.

Not applicable. Agilent manufacturing sites are not

located in habitat-protected areas or restored areas.

EN14

STRATEGIES, CURRENT ACTIONS, AND FUTURE PLANS FOR

MANAGING IMPACTS ON BIODIVERSITY.

Not applicable. Agilent manufacturing sites are not

located in habitat-protected areas or restored areas.

Not applicable. Agilent manufacturing sites are not located in habitat-protected areas or restored areas that could potentially be endangered or threatened.

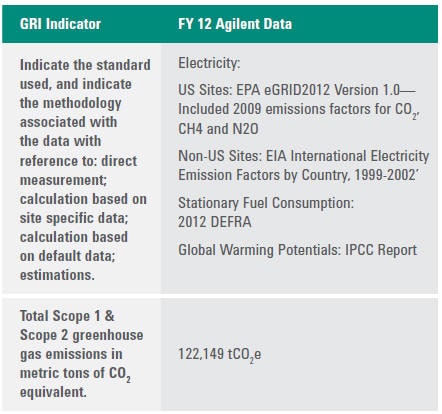

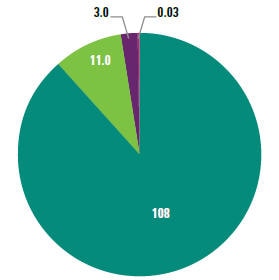

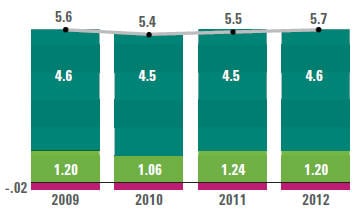

EN16 TOTAL DIRECT AND INDIRECT GREENHOUSE GAS EMISSIONS BY WEIGHT

Notes: 1 For FY 12 data emissions refer to EN 16 table.

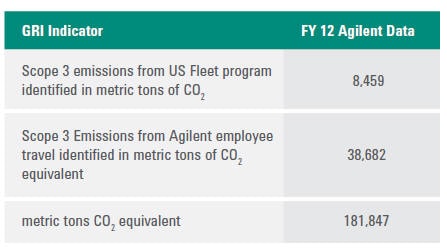

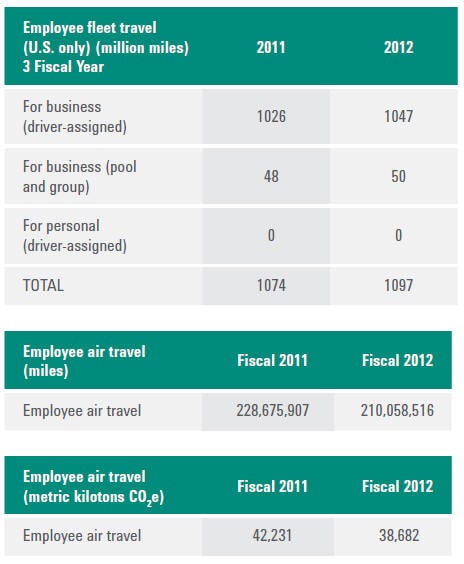

EN17 OTHER RELEVANT INDIRECT GREENHOUSE GAS EMISSIONS BY WEIGHT

Agilent is actively reducing emission of harmful gases by adapting its employee fleet and travel programs to minimize air pollutants.

In 2009 Agilent’s fleet vehicles moved from a V6 engine to a VI4, and we continue to use this smaller engine today for better environmental results. In 2012 Ford, Agilent’s North America fleet car provider, redesigned the I4 engine - 80 percent of the fleet resulting in an 11 percent decrease in fuel consumption. Agilent used Ford as a vendor for many reasons, one of which is its commitment to using sustainable, recycled and renewal materials. Another is its end-of-life process, which is helping to use 85 percent of the vehicle as recyclable waste.

In the future Agilent will continue to provide the needed tool-of-trade cars for field personnel while maximizing fuel and emission savings. We do have some hybrid cars in our fleet pools but do not find it economical to provide them in bulk, as we keep cars for only one year to keep the fleets updated with the most efficient cars. ROI for hybrid investment is a three- to five-year return or more.

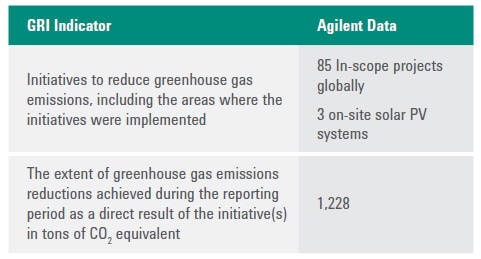

EN18 STRATEGIES, CURRENT ACTIONS, AND FUTURE PLANS FOR MANAGING IMPACTS ON BIODIVERSITY.

EN19

EMISSIONS OF OZONE-DEPLETING SUBSTANCES BY WEIGHT.

During the reporting period, only one site in Europe used

minute amount of CCI4 in a cleaning process. However,

this site will stop using ODC in 2013. There was no ODC

usage in our Asia Pacific sites.

EN20

NOX, SOX, AND OTHER SIGNIFICANT AIR EMISSIONS BY

TYPE AND WEIGHT.

Agilent will start reporting on these numbers from

2013 onward.

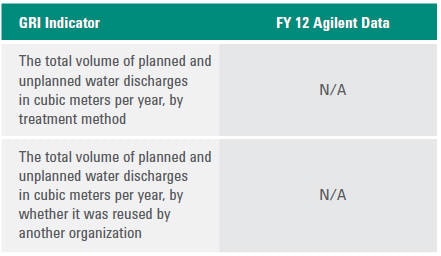

EN21 TOTAL WATER DISCHARGE BY QUALITY AND DESTINATION

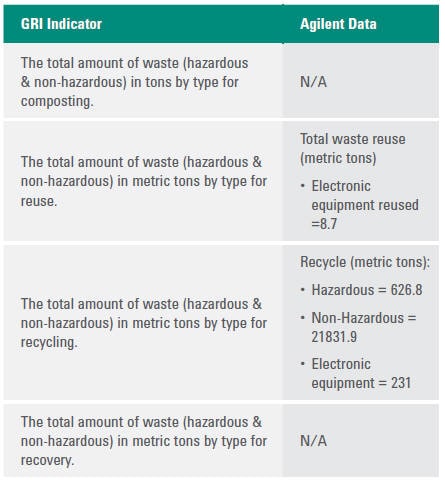

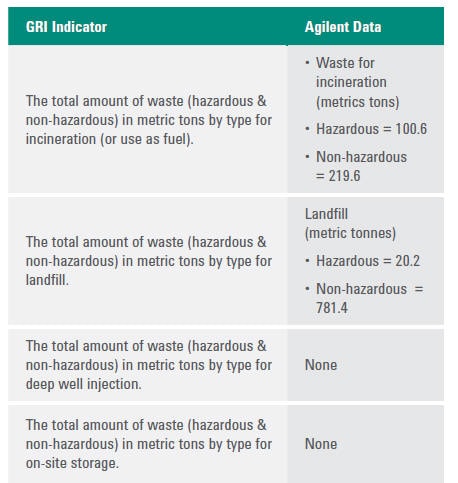

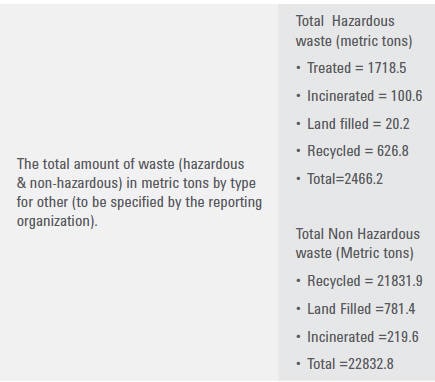

EN22 TOTAL WEIGHT OF WASTE BY TYPE AND DISPOSAL METHOD

Notes:

1 Total waste produced is calculated by adding total chemical waste and

total solid waste tonnage. Total waste calculated based on calendar

year (January 2012 – December 2012).

2 Chemical waste refers to chemical materials designated for final

disposition that exhibit characteristic that is hazardous or dangerous

per local regulatory requirements. This refers to materials that are

shipped offsite for treatment, recycling, incineration, and landfill; and

excludes electronic waste.

3 Solid waste refers to waste that is not included in chemical waste or

excess electronic equipment (e.g., garbage/trash, paper, cardboard,

glass, and furniture and construction debris).

Electronic Equipment is personal computers, computer monitors,

misc electronic test & manufacturing equipment, obsolete electronic

equipment, telephones, and spare or unused products from

manufacturing.

Electronic equipment - reused: electronic equipment sold or given to third party organizations such as charitable organizations or used equipment resellers. Agilent cannot guarantee that this equipment is re-used or resold. Agilent requires that equipment resellers dispose of any unsold electronic equipment according to state and local legal requirements.

Electronic equipment - recycled: electronic equipment that is sent directly to an electronic recycler with the intent of recycling the equipment’s components, sub-components, or material (e.g. precious metals). Agilent requires that recyclers dispose of all electronic equipment, components, and subcomponents according to state and local legal requirements.

EN23

TOTAL NUMBER AND VOLUME OF SIGNIFICANT SPILLS

Agilent had one significant chemical spill during the

reporting period. It was a 30-gallon sulfuric acid spill

at an Agilent site’s waste-treatment plant. It resulted

in a serious injury and the shutdown of the operation

for more than eight hours. The spill was contained

within the building; no sulfuric acid escaped the

waste-treatment plant.

EN24

WEIGHT OF TRANSPORTED, IMPORTED, EXPORTED, OR

TREATED WASTE DEEMED HAZARDOUS UNDER THE TERMS

OF THE BASEL CONVENTION ANNEX I, II, III, AND VIII,

AND PERCENTAGE OF TRANSPORTED WASTE SHIPPED

INTERNATIONALLY

Not applicable. Currently we do not have any transboundary

waste shipment, under the Basel Convention.

EN25

IDENTITY, SIZE, PROTECTED STATUS, AND BIODIVERSITY

VALUE OF WATER BODIES AND RELATED HABITATS

SIGNIFICANTLY AFFECTED BY THE REPORTING

ORGANIZATION’S DISCHARGES OF WATER AND RUNOFF

No value of water bodies and related habitats are

impacted by any discharges of water or runoff by

Agilent’s operations.

EN26

INITIATIVES TO MITIGATE ENVIRONMENTAL IMPACTS

OF PRODUCTS AND SERVICES, AND EXTENT OF IMPACT

MITIGATION

Initiatives to mitigate the most significant environmental

impacts of products/service groups:

- Agilent continued to make significant progress toward complying with EU Restriction of Hazardous Substances (RoHS). Agilent’s Electronic Measurement Group (EMG) now has more than 2,000 products designed to be compliant with EU RoHS four years ahead of the 2017 regulatory deadline for Test and Measurement products. This effort has had positive implications on Agilent’s materials use, regulatory compliance, waste impacts and customer satisfaction.

- For the first time, Agilent conducted a greenhouse gases “hot spot” analysis throughout our indirect supply chain. Our goal is to increase Agilent’s use of suppliers who are environmental leaders in their respective categories. This is one step in our long journey to lower Agilent’s carbon footprint and reduce our companywide greenhouse gas emissions.

- We have updated Agilent’s supplier code of conduct to ensure compliance with Environmental, Health, Safety and Social Responsibility guidelines throughout our supply chain. Suppliers are now accountable for ensuring that their subcontractors also comply with EHSSR guidelines, with responsibility for taking corrective action as necessary.

- Agilent now includes a corporate citizenship overview in all new employee orientation, ensuring that social and environmental responsibility will continue to be a part of our culture moving forward.

- Agilent continued its robust communication of our General Specification for the Environment (GSE) with its strategic suppliers, resulting in greater than 95 percent response rate. This effort enables Agilent and its suppliers to comply with major environmental regulations on material use, product packaging and labeling.

- Agilent established targets to reduce water consumption by 10 percent in the next 3 years to reduce impact on environment and natural resources.

EN27 PERCENTAGE OF PRODUCTS SOLD AND THEIR PACKAGING MATERIALS THAT ARE RECLAIMED BY CATEGORY

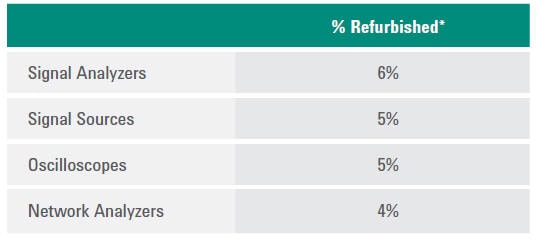

- Agilent’s material management practices are based on the principle of Reduce, Reuse and Recycle for products sold and packaging material utilized. For example, during the reporting period, at one operation we started to replace foam packaging to recyclable PET (polyethylene terephthalate) cell packaging for Gas Chromatography columns. As a result, packaging material weight was reduced on average by approximately 20 percent. At another manufacturing location, we began utilizing the High Recycled Content (HRC) foam for packaging, resulting in positive environmental impact and material/freight savings. The HRC foam is constructed using up to 65 percent recycled PE material. The conventional foam used previously could only use up to 15 percent recycled PE material. At the same time, the robust construction of the HRC foam has allowed us to protect the product using less material, thus reducing the overall packaging size by more than 30 percent. By using recycled content in the HRC foam, we are benefiting the environment by reducing the amount of material that enters the waste stream. Agilent also deployed a Migration of Support strategy that recycles instruments from trade-in programs to continue legacy support for mature equipment that customers want to maintain. This strategy minimizes our environmental impact of building new components while continuing to provide support on older technology.

- Agilent’s Remarketing Solutions Division is dedicated to recovering older instruments for the purpose of resale. For a certain segment of our customers (startups, academics, etc.), these pre-owned instruments offer a competitively priced alternative to buying a new instrument. As a company, we are using fewer environmental resources to manufacture new products to meet this customer demand.

- Agilent offers a variety of trade-in programs specifically designed to help customers safely dispose of or recycle used instrumentation. The program is currently deployed in several countries, with expansion of these programs being considered wherever possible.

- During the reporting period, Agilent also donated reclaimed products to academic institutions. Agilent gave 171 pieces of electronic measurement equipment to Sonoma State University, and 78 similar items were donated to the University of California, Davis.

* % Refurbished = Sales price of refurbished shipments / Sales price of total shipments (new + refurbished).

EN28 MONETARY VALUE OF SIGNIFICANT FINES AND TOTAL NUMBER OF NON-MONETARY SANCTIONS FOR NONCOMPLIANCE WITH ENVIRONMENTAL LAWS AND REGULATIONS

- In FY12, Agilent reported a total of 36 alleged regulation compliance violations. However, only one incident resulted in a monetary fine ($6,800). This occurred at the Manesar, India site.

<<

Economic Performance

Social : Labor Practices and Decent Work Indicators

>>