InfinityLab LC/MSD iQ

Adding mass detection to your lab’s analytical toolbox can dramatically increase analytical confidence. The InfinityLab LC/MSD iQ enables you to quickly confirm compounds and provide more specificity and selectivity than a UV detector, even for compounds that are chromatographically unresolved. You are not only adding more clarity and certainty to your lab, now you can also be assured that you’re choosing a sustainable option.

The InfinityLab LC/MSD iQ offers:

- Reduced energy consumption

- Less material used to manufacture

- Smaller packaging, improved shipping sustainability

- Sustainable, recycled product and packaging content

- End-of-life tack-back incentives to ensure proper recycling

Additional Information

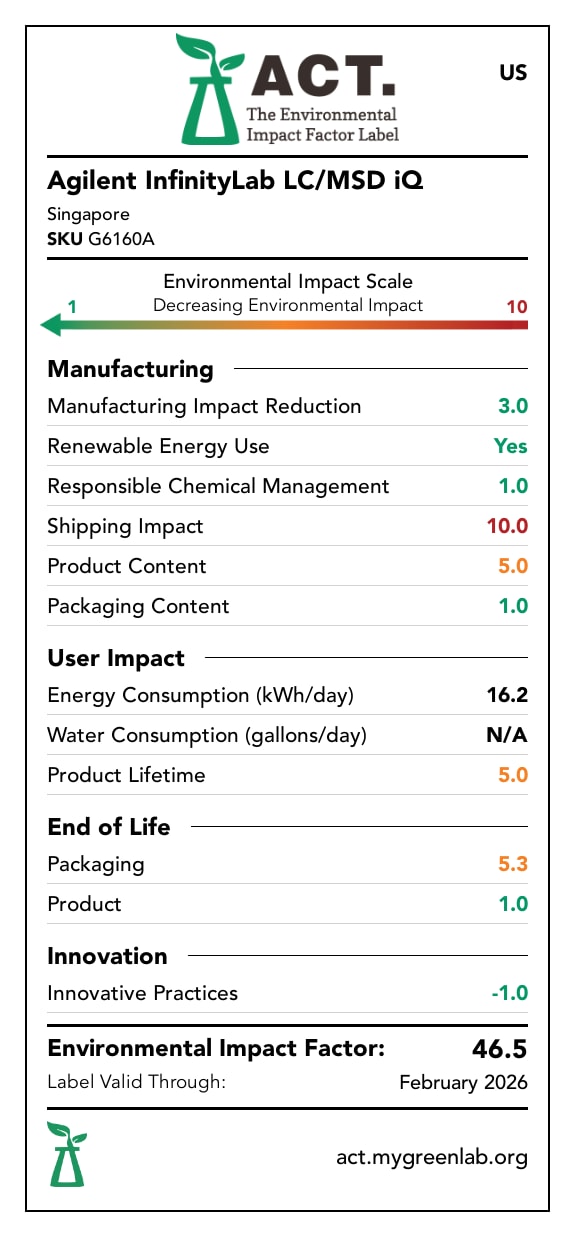

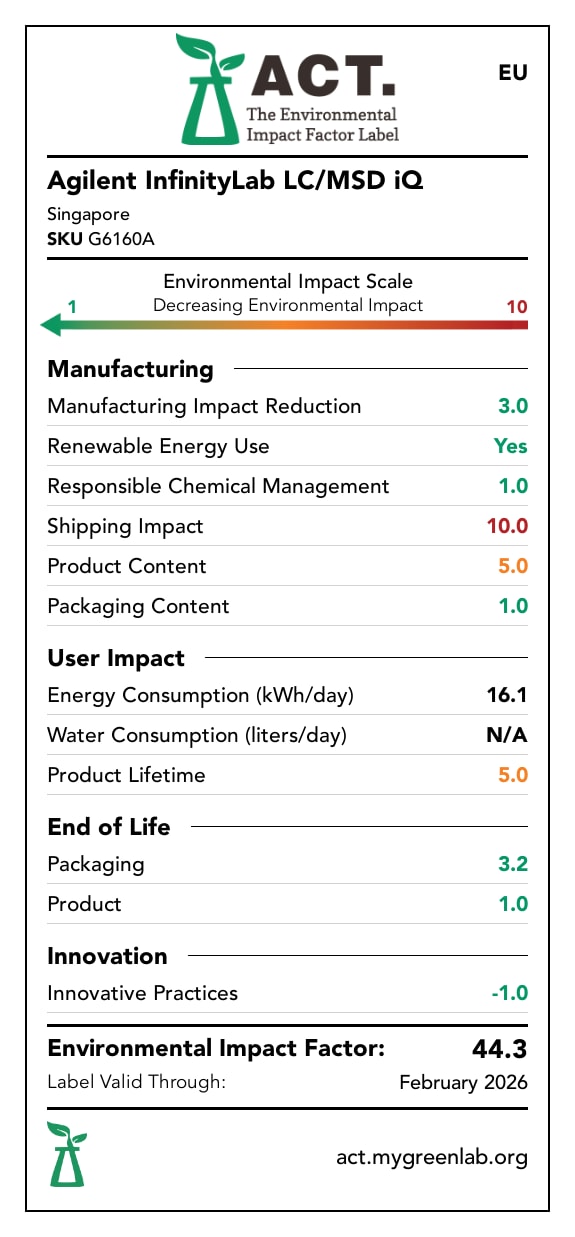

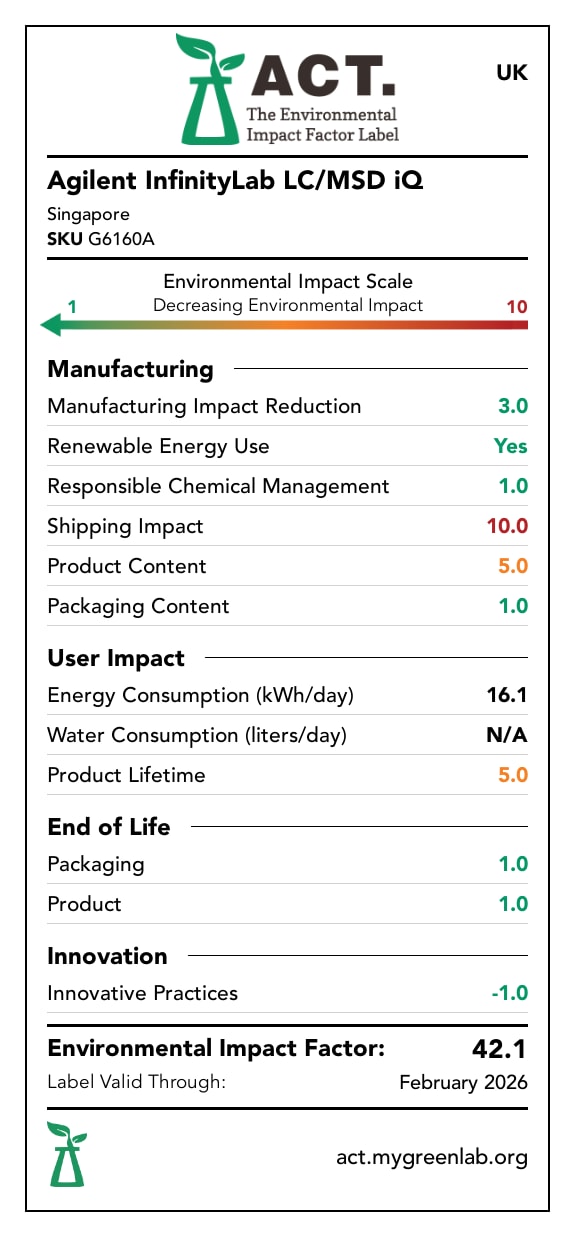

Manufacturing Impact Reduction

The Singapore facility that manufacturers the Agilent mass spectrometry products has implemented measures to reduce the facility's overall energy and water consumption. Initiatives include installing water-saving technology in the washrooms and pantries as well as upgrading old equipment and completed a LED retrofit project.

Renewable Energy Use

The Singapore manufacturing plant that produces Agilent mass spectrometry products has 2.5 megawatt photovoltaic system which generates an estimated 21% of site's power.

Responsible Chemical Management

Agilent has implemented policies and procedures to understand, manage and communicate hazardous chemistries throughout the value chain. Suppliers must ensure their raw materials comply with Agilent's General Specification for the Environment (GSE) which screens for hazardous chemistries such as EU REACH SVHCs and Proposition 65 chemicals. Further, the Agilent mass spectrometry products are EU RoHS compliant and the Singapore manufacturing facility is ISO 14001 certified.

Shipping Impact

The Agilent mass spectrometry products are manufactured in Singapore. The US market is serviced via Agilent's distribution center in Memphis, Tennessee and the EU/UK market is serviced via Agilent's distribution center in Waghäusel, Germany.

Product Content

The Agilent mass spectrometry models were dematerialized relative to previous versions of the units. This dematerialization was driven by a reduction in size for all three models. Reductions to the sheet metal and other supporting components resulted in almost 50% dematerialization for the Ultivo units and almost 30% for the InfinityLab LC/MSD unit.

Packaging Content

The Agilent mass spectrometry products are packaged using cardboard, poly bags, and foam. The cardboard contains approximately 55% recycled paper. Furthermore, the packaging system for the Ultivo Triple Quadrupole LC/MS and InfinityLab LC/MSD iQ models was dematerialized relative to the packaging system used for the previous model. This dematerialization in packaging materials was driven by a reduction in size for all three models.

Energy Consumption

The Agilent mass spectrometry products consume energy during the products' use phase. The energy usage was measured under normal operating conditions and assumes the product is in active mode 24-hours a day.

Water Consumption

The Agilent mass spectrometry products do not require water to function properly during the use phase.

Lifetime Rating

The Agilent Value Promise guarantees that the Agilent mass spectrometry products will, at a minimum, have a lifetime of 10 years.

Packaging End-of-Life

The Agilent mass spectrometry products are packaged using cardboard, poly bags, and foam. In the US, the cardboard is readily recyclable while the plastic bag and foam are recyclable, the infrastructure is not available in the majority of the market. In select EU member countries, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life. In the remaining EU countries, the cardboard box is readily recyclable while the plastic packaging materials are recycled, landfilled or incinerated via a waste-to-energy recovery process depending on the EU country and its available infrastructure. In the UK, Agilent participates in an Extended Producer Responsibility (EPR) scheme to support the take-back and responsible management of the packaging materials at their end-of-life.

Product End-of-Life

Agilent offers a take-back program for its mass spectrometry customers in US, EU and UK markets.