Access Agilent eNewsletter January 2017

Ask the Expert: Is there a simple, cost-effective alternative to traditional manual operation while improving precision in GC analysis?

Remko van Loon, Agilent GC Application Specialist

Use of mechanical regulators are susceptible to drift over time. Drift can be averted with electronic pneumatics regulation (EPR) technology. EPR also eliminates the need for inconvenient bubble meters to measure and adjust the flows in your system. Additionally, temperature and barometric compensation significantly improves retention time and baseline stability compared to traditional manual pneumatic‑based systems that are using gauges and diaphragms.

A newly introduced electronic pneumatics regulation (EPR) for the Agilent 7820A GC is a simple, precise, and cost-effective alternative to traditional manual pneumatic operation for select inlets and detectors. EPR provides the simplicity of manual operation with high precision digital display of pressures and flows and superior ease-of-use as compared to traditional manual pneumatics systems. In this article, our experts answer common questions regarding the use of EPR technology.

How does EPR work in the lab?

Pressure or flow in an Agilent 7820A GC equipped with EPR can easily be increased or decreased using the + or – key on the software keypad. The pressure or flow values are displayed in real time on the system’s display and software keypad as an example is shown in Figure 1.

Agilent EPR technology supports split/splitless and packed column inlets, as well as the flame ionization (FID) and thermal conductivity detector (TCD). Using EPR for the split/splitless inlet, you can easily change the inlet pressure and total flow. The split flow and split ratio will automatically change with total flow adjustments.

The Agilent 7820A GC can be configured with EPR for both inlets and detectors. However, as detector flows are often set only once—you have the ability to configure EPR regulation for just the detectors—allowing the user to keep full flow control over the inlets using Electronic Pneumatics Control (EPC).

Another key advantage of EPR over traditional manual pneumatics is the ability to save a record of the actual pressure and flow information for each run with the data file.

How does EPR technology compare to EPC equipment in a head-to-head match-up?

To check the performance of Agilent EPR technology, our experts designed a comparison between the Electronic Pneumatics Controller and Electronic Pneumatics Regulator. For this experiment, a mixture of even hydrocarbons from C10 to C40 at approximately 50 mg/L each in n-heptane was analyzed. We were using a single Agilent 78020A GC and capillary column and applied the same constant column head pressure on both setups. More information about the test setup and experimental conditions can be found in Agilent technical overview 5991-7406EN.

Figure 2. Identical retention times for the EPR and EPC on a 7890A GC in comparison experiment.

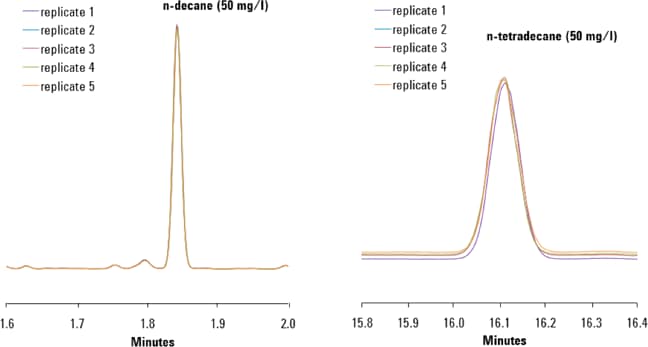

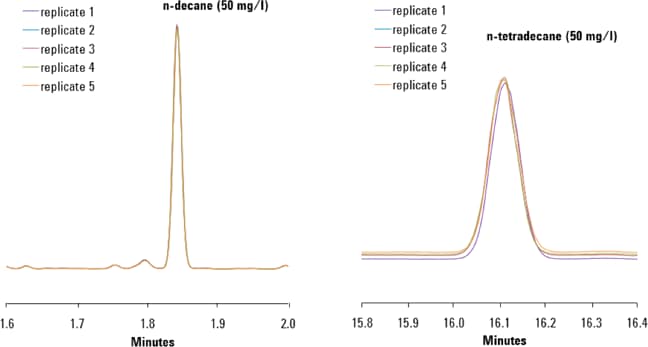

Figure 3. Overlay of 5 replicates for the hydrocarbon standard from the repeatability experiment.

| Repeatability (RSD%, n=10) | ||

|---|---|---|

| Compound | Area | Retention time |

| C10 | 0.44 | 0.027 |

| C12 | 0.50 | 0.016 |

| C14 | 0.52 | 0.009 |

| C16 | 0.55 | 0.006 |

| C18 | 0.52 | 0.008 |

| C20 | 0.55 | 0.011 |

| C22 | 0.59 | 0.008 |

| C24 | 0.52 | 0.008 |

| C26 | 0.50 | 0.008 |

| C28 | 0.52 | 0.008 |

| C30 | 0.49 | 0.007 |

| C32 | 0.53 | 0.008 |

| C34 | 0.52 | 0.012 |

| C36 | 0.50 | 0.013 |

| C38 | 0.66 | 0.027 |

| C40 | 0.45 | 0.023 |

Table 1. Excellent area and retention time repeatability for 7820A GC with EPR.

Figure 2 clearly shows that the retention times match for the two technologies over the whole sample range. In addition, ten consecutive runs—using EPR flow regulation for both the inlet and detector—were analyzed to study the system’s repeatability. Excellent relative standard deviations for peak area were found at approximately 0.5% RSD. Stable retention times and detector baselines were obtained using Agilent EPR technology. Retention time repeatability was measured at 0.03% RSD and lower. Detailed results for all compounds are shown in Table 1. Overlay of five replicates from the repeatability experiment are depicted in Figure 3.

Agilent 7820A GC with EPR delivers flexibility, precision, and affordability

The Agilent 7820A GC with Electonic Pneumatics Regulation combines the simplicity of manual operation with high precision in a cost-effective design. With EPR, you can manually adjust pressures and flows electronically, while measured values are displayed on the system’s display and software keypad. A record of actual pressures/flows can be saved for each run with the data file.

When you need flexible, reliable gas chromatography systems and software for complex research, we have a range of solutions to meet your needs. For more information, contact an Agilent representative today.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – January 2017

All articles in this issue

Best practices for food safety laboratories: highlights from inaugural Agilent—AOAC workshop

Best practices for food safety laboratories: highlights from inaugural Agilent—AOAC workshop ICP-MS and ICP-OES methodology enables comprehensive analysis and quantification of elemental extractables and leachables

ICP-MS and ICP-OES methodology enables comprehensive analysis and quantification of elemental extractables and leachables Ask the Expert: Is there a simple, cost-effective alternative to traditional manual operation while improving precision in GC analysis?

Ask the Expert: Is there a simple, cost-effective alternative to traditional manual operation while improving precision in GC analysis? Case study: Agilent customer collaboration delivers robust LC-QQQ method to quantify vitamin B12 absorption

Case study: Agilent customer collaboration delivers robust LC-QQQ method to quantify vitamin B12 absorption Accelerate analysis of mineral oil (MOSH/MOAH) with ready-to-go online LC-GC/FID coupling

Accelerate analysis of mineral oil (MOSH/MOAH) with ready-to-go online LC-GC/FID coupling Preconfigured GC/MS/MS analyzer puts you on the fast track to pesticide analysis

Preconfigured GC/MS/MS analyzer puts you on the fast track to pesticide analysis Tip: Getting the best value from your UHPLC analyses

Tip: Getting the best value from your UHPLC analyses

Figure 1

Gas flow and pressures can easily be adjusted using the + and – keys.

Figure 2

Identical retention times for the EPR and EPC on a 7890A GC in comparison experiment.

Figure 3

Overlay of 5 replicates for the hydrocarbon standard from the repeatability experiment.