Access Agilent eNewsletter September 2016

Direct heating delivers a new paradigm in gas chromatography analysis

Jim Gearing, Agilent Product Manager, GC

Over the past 50 years, gas chromatography has successfully evolved to be a productive and critical tool for research, manufacturing, and regulatory laboratories. However, with the increasing shift in chromatography expertise moving from the scientist to the analytical instrument, the laboratory is pressed to maximize instrument uptime and productivity.

One of the biggest limiting factors in preventing a GC from running non-stop is the inherent need for time consuming maintenance, calibrations, and performance validation routines. To address these challenges, Agilent examined tools and techniques aimed at improving those three critical and time consuming tasks. The end result: to significantly improve these performance characteristics and methodologies, a complete redesign of the enabling technology was required. In other words, the oven needed to be completely reimagined.

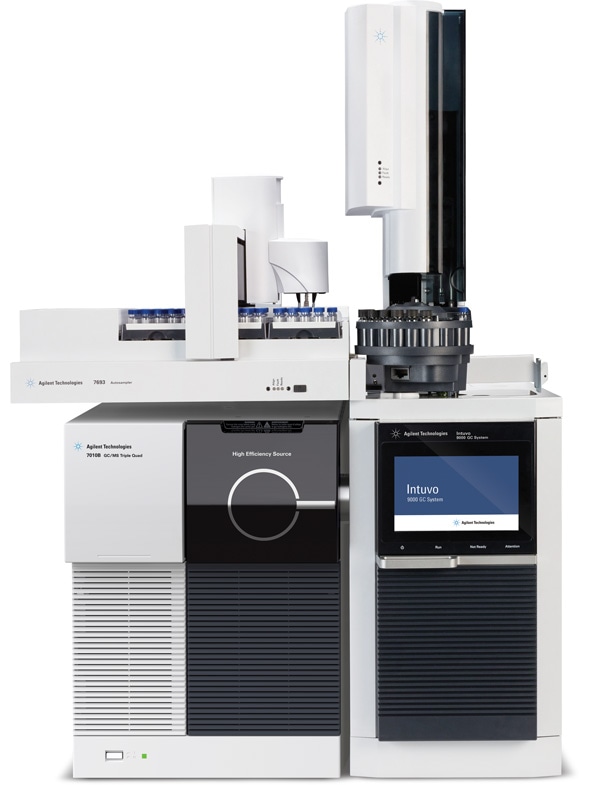

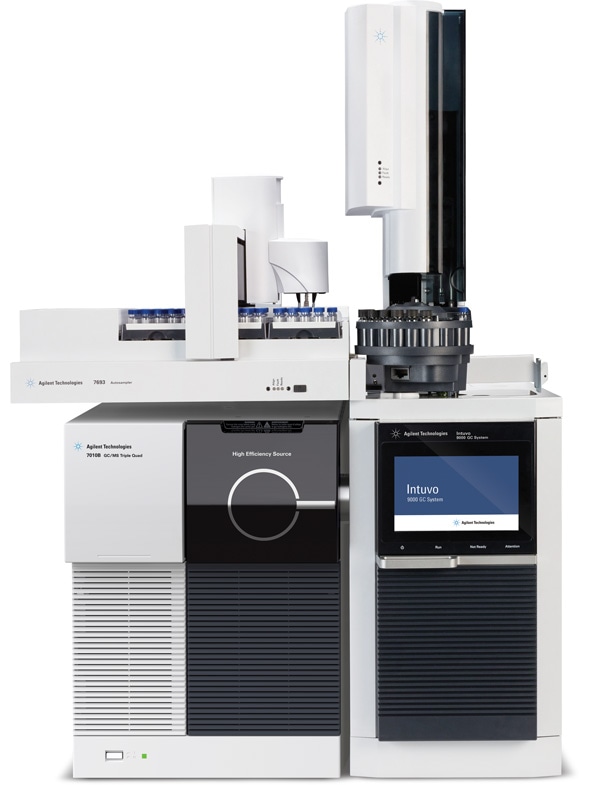

Figure 1. Agilent Intuvo 9000 GC System.

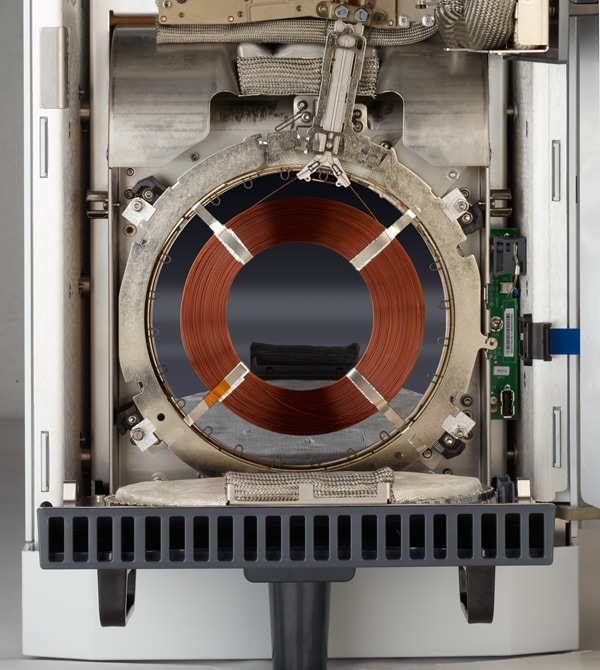

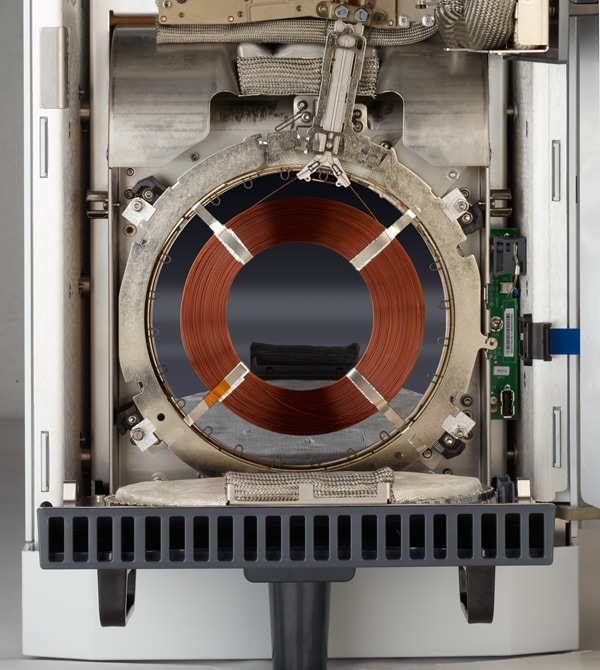

Figure 2. Agilent Direct Heating design.

Figure 3. Simple and easy-to-replace components.

Reimagining the GC oven for improved uptime and maximum productivity

The oven that is recognized today as the industry standard is the air-bath oven. The concept of heating a GC column through convection has been improved a number of times over the last several decades, and by most accounts, has been pushed and modified to its limit. However, with these advances, the heating and cooling cycles can cause the nut and ferrule fittings to fail over time.

What’s more, the closed air-bath oven requires compensation for matrix effects on the column, which results in the need of retention gap or column clipping. And finally, the complexity of implementing mid or post column backflush can be difficult to implement. Now, the design of an incredibly clever direct heating oven has knocked down barriers that the chromatographer would never have imagined being removed (Figure 1).

Direct heating provides for quicker results, better column protection, and improved fittings

To implement direct heating, not only did the oven get redesigned, so did the column. First, let’s look at the column. To ensure that the operator would not have to deal with changes in the interpretation of the chromatogram, the GC column material did not change. The Agilent GC column lengths, diameters, and chemistries offered are all identical. However, the column has now been wound in a planar design that allows the use of a planar heating device (Figure 2). By eliminating the air-bath oven space and minimizing the amount of mass involved in the design, the heat up and cool down times can be optimized. In addition to time of analysis being improved, the new Agilent Direct Heating design opens the door for more efficient column protection and gas tight fitting capabilities.

Retention gap technology redefined

The enabling technology of direct heating allows the creation of a new type of flow path efficiency. This inert flow path has eliminated the need for a retention gap, as well as the need to clip a column. Now, the retention gap has been relegated to a simple, disposable, and easy-to-replace component (Figure 3). In addition to better up-front column protection, the new flow-path technology makes setting up backflush simple and non-technical. This added protection has been proven to advance the sample throughput capabilities of a typical GC column in most applications. The extended lifetime equates to more uptime and more productivity.

Ferrule-free sample path

Ferrules are now being eliminated from the sample flow path, and from your laboratory. A non-technique based faceplate seal has been developed to ensure leak-free connections time after time. The seal is confirmed with a tactile and audible torque driver, making the connection robust and routine.

Agilent direct heating innovation leads to additional tech advancements

To advance gas chromatography (GC), we realized that it would require more than just an improvement or enhancement to current technology. A GC transformation would require Agilent to reimagine the technology starting with the heating scheme. This development turned out to be a springboard to several other technological advancements that make the Agilent Intuvo a paradigm-breaking GC innovation.

Agilent delivers a huge selection of gas chromatography solutions for today’s busy labs

Agilent provides a wide array of gas chromatography systems, analyzers, sample prep tools, columns, and supplies that help modern laboratories maintain peak performance, maximize instrument uptime, and meet the toughest analytical challenges. Whether your lab needs flexible, reliable gas chromatography hardware and software for complex research; simple, robust systems for routine production environments; fast, rugged, portable solutions for real-time measurements in the field; or high-performance gas chromatography consumables, Agilent has the GC solution to meet your demands. Contact an Agilent representative today to learn more.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – September 2016

All articles in this issue

High-resolution, efficient quantification of aggregates in protein therapeutics with Agilent 1290 Infinity II 2D-LC Solution

High-resolution, efficient quantification of aggregates in protein therapeutics with Agilent 1290 Infinity II 2D-LC Solution Fast determination of bitter, clove-like flavor in beer with the Agilent 1290 Infinity II LC

Fast determination of bitter, clove-like flavor in beer with the Agilent 1290 Infinity II LC Direct heating delivers a new paradigm in gas chromatography analysis

Direct heating delivers a new paradigm in gas chromatography analysis Implementing an extractable and leachable (E&L) study from a pharmaceutical product by high resolution QTOF LC-MS

Implementing an extractable and leachable (E&L) study from a pharmaceutical product by high resolution QTOF LC-MS Multi-omic analysis helps researchers to integrate complex omics data in cancer research

Multi-omic analysis helps researchers to integrate complex omics data in cancer research Gain control—Agilent 490-PRO Micro GC optimizes process monitoring

Gain control—Agilent 490-PRO Micro GC optimizes process monitoring

Figure 1

Agilent Intuvo 9000 GC System.

Figure 2

Agilent Direct Heating design.

Figure 3

Simple and easy-to-replace components.