Access Agilent eNewsletter November 2016

Ask the Expert: How can I analyze virtually any polymer, from paints to polyolefins?

Graham Cleaver, Agilent Business Development Manager for ELSD/GPC/RID

Figure 1. Agilent 1260 Infinity II system, coupled with MDS, delivers highly accurate molecular weights and distribution profiles.

Gel Permeation Chromatography (GPC) has become established as one of the preferred techniques for characterizing polymers. Molecular weights and distributions are useful in predicting processibility, structural properties, and the way a polymer will perform in a given application. Agilent is the only manufacturer of all the components required for high performance GPC. The Agilent 1260 Infinity II GPC system takes polymer characterization to complete automation, high precision, and excellent reproducibility.

When coupled with either the linear range mixed bed or individual pore size columns, calibrated with standards and data processed by the Agilent GPC software, the Agilent 1260 Infinity II delivers highly accurate molecular weights and distribution profiles. When coupled with the MDS, absolute molecular weights and structural information take polymer analysis to the next level (Figure 1).

Q. How can any polymer be analyzed?

The Agilent 1260 Infinity II system with refractive index detection is the instrumentation required for the majority of polymers based on carbon and hydrogen with different side groups.

Quite often polymers are not UV active and do not possess a UV chromophore. The solvent of choice is often tetrahydrofuran (THF). Occasionally the polymer’s physical properties can require an alternative solvent. One example is epoxy resins. A number of polymers, such as polyvinyl alcohol (PVA), are water-soluble. The majority of polymers can be characterized using an Agilent 1260 Infinity II system equipped with refractive index.

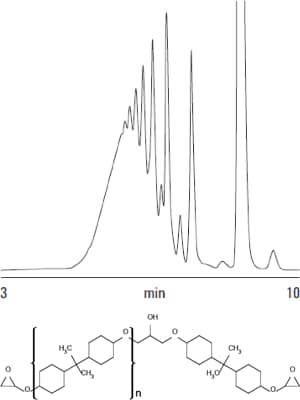

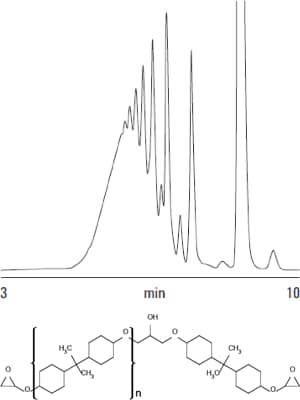

Figure 2. Analysis of epoxy resins using Agilent 1260 Infinity II GPC system with Agilent PLgel column.

Figure 3. Chromatogram of water soluble polyvinyl alcohol using the Agilent 1260 Infinity II with Agilent PL aquagel-OH SEC columns.

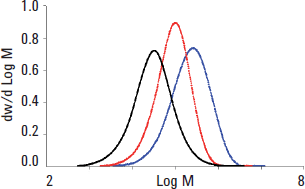

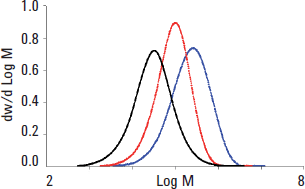

Figure 4. Overlay of the molecular weight distributions of two samples of polyamide, clearly showing the difference between the two materials.

Figure 5. Data obtained on three samples of polyethylene using the Agilent PL-GPC220 equipped with refractive index and viscometry detectors.

Q. Which GPC system is best suited for analyzing a varied range of polymers?

The Agilent 1260 Infinity II GPC system is ideal for analyzing a wide range of polymers. Let’s take a look at some examples:

Epoxy resins

The way that paint adheres to a surface and the speed at which it dries is related to physical properties. Epoxy resins consist of very low molecular weight materials, which are important in the way the polymer performs (Figure 2). In testing paints, precise flow rates, high column resolution, and stable baselines ensure accurate, reproducible results.

Poly vinyl alcohol

GPC is a convenient method of fingerprinting materials like poly vinyl alcohol for quality control, and is more informative in production control and end-use performance evaluation. The Agilent 1260 Infinity II system, coupled with easy to use Agilent GPC software and an autosampler that delivers high sample throughput, allows for unattended, automated analysis that can save time (Figure 3) and deliver the answers required for batch-to-batch reproducibility.

Polyamides

Analysis of a polymer, such as Nylon, is a challenge because solubility is limited to HFIP and m-cresol. Molecular weight influences many of the key physical parameters−including strength, brittleness, melt flow, and how easily the material is processed. Nylon is a common polyamide that has a range of uses, most commonly in clothing. Higher temperature is required to reduce the eluent viscosity. Temperature stability is paramount in obtaining accurate results (Figure 4).

Polyolefins

Analysis of polyethylene and polypropylene is a challenging application that requires a unique solution. The Agilent PL-GPC220 GPC/SEC system maintains samples at the high temperatures required to keep these polymers in solution. Additionally, the Agilent PL-GPC220 accommodates RID, light scattering detection, and viscometry in a high precision oven for stable baselines and high quality results (Figure 5).

Agilent offers powerful solutions for polymer analysis

Our experts have provided you with answers and solutions for analyzing virtually any polymer.

Gain more knowledge about polymer analysis from our comprehensive library of reference guides and application notes. Take a moment and explore these trending applications: Biodegradable polymers—analysis of biodegradable polymers by GPC/SEC, Analysis of Polymers by GPC/SEC – Energy & Chemicals Applications, GPC/SEC Food Testing, and GPC/SEC Pharma.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – November 2016

All articles in this issue

-

Agilent 7010B and 7000D QQQ GC/MS systems expand your lab in multiple dimensions

Agilent 7010B and 7000D QQQ GC/MS systems expand your lab in multiple dimensions -

Fast, accurate analysis of SVOCs with Agilent 9000 Intuvo GC

Fast, accurate analysis of SVOCs with Agilent 9000 Intuvo GC -

Integrated workflow simplifies automated calculation of antibody-drug conjugate (ADC) drug-to-antibody ratio (DAR)

Integrated workflow simplifies automated calculation of antibody-drug conjugate (ADC) drug-to-antibody ratio (DAR) -

Tips & tricks:

Tips & tricks:

How to simplify troubleshooting in your GC lab using Agilent ADM Flow Meter -

Agilent collaborates with BioPharma thought leaders in India to advance biosimilar characterization

Agilent collaborates with BioPharma thought leaders in India to advance biosimilar characterization -

Achieve fast, high throughput size exclusion chromatography of mAbs and ADCs using Agilent AdvanceBio SEC columns

Achieve fast, high throughput size exclusion chromatography of mAbs and ADCs using Agilent AdvanceBio SEC columns -

Ask the Expert: How can I analyze virtually any polymer, from paints to polyolefins?

Ask the Expert: How can I analyze virtually any polymer, from paints to polyolefins? -

Agilent LC/MS/MS solutions provide effective identification and quantitation of contaminants in botanical drug supplements

Agilent LC/MS/MS solutions provide effective identification and quantitation of contaminants in botanical drug supplements -

Agilent JetClean self-cleaning ion source means you clean less, analyze more

Agilent JetClean self-cleaning ion source means you clean less, analyze more -

High-throughput N-linked glycan profiling of monoclonal antibodies using Agilent integrated solution

High-throughput N-linked glycan profiling of monoclonal antibodies using Agilent integrated solution

Figure 2

| Conditions | |

|---|---|

| Column | Agilent PLgel 3 µm MIXED-E, 300 x 7.5 mm (p/n PL1110-6300) |

| Eluent | THF |

| Flow rate | 1.0 mL/min |

| Detector | UV, 254 nm |

Analysis of epoxy resins using Agilent 1260 Infinity II GPC system with Agilent PLgel column.

Figure 3

| Conditions | |

|---|---|

| Column | 2 x PL aquagel-OH 40 8 µm, 300 x 7.5 mm |

| Eluent | 0.25 M NaNO3 + 0.01 M NaH2PO4 at pH 7 |

| Flow Rate | 1.0 mL/min |

| Detection | RI |

Chromatogram of water soluble polyvinyl alcohol using the Agilent 1260 Infinity II with Agilent PL aquagel-OH SEC columns.

Figure 4

| Conditions | |

|---|---|

| Column | 2 × Agilent PLgel 10 µm MIXED-B, 7.5 × 300 mm |

| Eluent | m-Cresol |

| Injection volume | 200 µL |

| Flow rate | 1.0 mL/min |

| Temperature | 100 °C |

| Detector | DRI |

Overlay of the molecular weight distributions of two samples of polyamide, clearly showing the difference between the two materials.

Figure 5

| Conditions | |

|---|---|

| Samples | Polyethylenes |

| Columns | 3 x PLgel Olexis, 300 x 7.5 mm |

| Eluent | TCB + 0.015% BHT |

| Flow Rate | 1.0 mL/min |

| Inj Vol | 200 µL |

| Temp | 160 oC |

| Detector | RID and Viscometer |

Data obtained on three samples of polyethylene using the Agilent PL-GPC220 equipped with refractive index and viscometry detectors.