Access Agilent eNewsletter April 2016

Analyze low-ppm levels of active sulfur compounds with inert sample path on the Agilent 490 Micro GC

Remko van Loon, Agilent GC Application Specialist

Trace gas analysis is a challenge, particularly when you must analyze low levels of sulfur-containing compounds like hydrogen sulfide and carbonyl sulfide. The ability to analyze at low-ppm levels permits better quality control and gives more reliable results, but requires an analytical system that provides maximum inertness. Agilent UltiMetal deactivation of critical stainless steel surfaces in the Agilent 490 Micro GC enables the lowest possible detection limits for active sulfur-containing analytes.

Flexible system can contain up to four miniature GCs

For trace gas and other analyses, you can equip the Agilent 490 Micro GC with one to four independently controlled column channels. Each column channel is a complete, miniaturized GC with:

- Electronic carrier gas control

- Micro-machined injector

- Narrow-bore analytical column

- Micro thermal conductivity detector (µTCD)

This setup provides fast gas analyses, with typical run times of only 30 to 90 seconds.

Recent design enhancements for the Agilent 490 Micro GC give you reduced detection limits for trace gases. [1] To demonstrate the latest capabilities, we used the system equipped with an Agilent J&W PoraPLOT U column module.

Figure 1. The updated sample inlet design for the Agilent 490 Micro GC reduces surface activity and minimizes the potential for leaks.

Figure 2. Trouble-free separation of hydrogen sulfide and carbonyl sulfide from the other compounds in biogas and natural gas on the Agilent J&W PoraPLOT U column channel.

Enhanced sample inlet design with UltiMetal surface deactivation

This system configuration features an improved sample inlet design (Figure 1) with a fixed 1/16-inch heated sample connector at the rear of the instrument, or an optional unheated inlet on the front. The front inlet enables manual injections with a gas-tight syringe. The new sample inlet provides maximum flexibility to analyze your gas samples, and uses proprietary Agilent UltiMetal technology for metal surface deactivation of the sample flow path. The surface treatment is applied to the entire inlet, from the sample connector union to the tubing connected to the injector. Recent sample inlet enhancements include vacuum-brazed connections to minimize nut and ferrule connections, as well as an O-ring-free design for a leak-free sample path. [2]

Hydrogen sulfide and carbonyl sulfide: well-separated from gas matrix

An Agilent J&W PoraPLOT U column module is an ideal choice to separate hydrogen sulfide and carbonyl sulfide from the matrix of energy-rich sample streams, such as biogas or natural gas. Figure 2 shows that these sulfur compounds elute between ethane and propane. The excellent separation enables easy peak integration and identification, for reliable analyses.

The Agilent 490 GC Biogas Analyzer and Agilent 490 Micro GC Natural Gas Analyzers are equipped with the same PoraPLOT U column channel and sample path deactivation. [3,4] Results and conclusions shown here are applicable to these preconfigured and factory-tuned instruments as well.

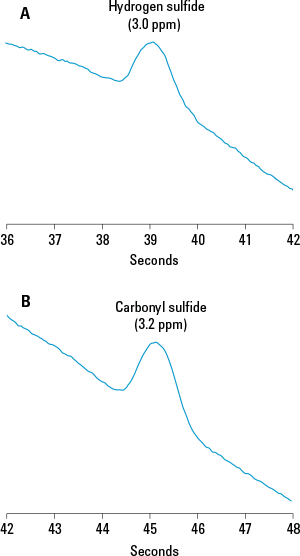

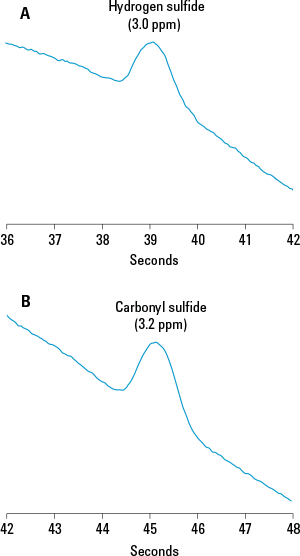

Figure 3. Successful analysis of 3 ppm hydrogen sulfide and carbonyl sulfide on the Agilent 490 Micro GC with inert sample path.

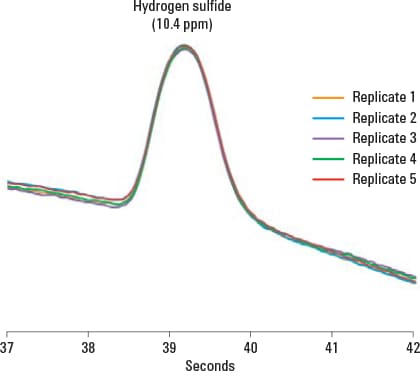

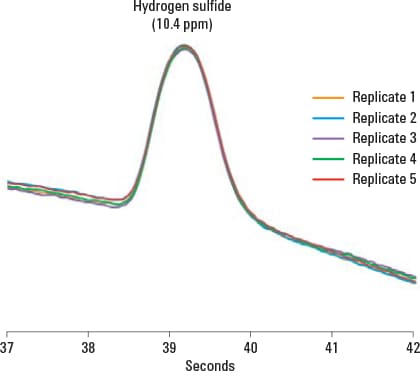

Figure 4. Repeatable analyses: overlay of five replicate runs for 10 ppm hydrogen sulfide.

Sulfur compounds detected down to 3 ppm

Figure 3 shows an analysis of 3.0 ppm hydrogen sulfide and 3.2 ppm carbonyl sulfide. Even though baseline noise is visible in these zoomed chromatograms, the figure clearly shows that the Agilent 490 Micro GC with an inert sample inlet can analyze low-ppm levels of these sulfur compounds.

Excellent repeatability

In addition to low limits of detection, reliable results demand instrument repeatability. To confirm the instrument’s performance, we determined repeatability of both concentration and retention time.

Retention time repeatability for 10 consecutive analyses was between 0.03 and 0.08%. Peak area repeatability, measured as external standard (ESTD) concentration, was 0.5 to 1.0% relative standard deviation (RSD) for the 10-ppm level, and 1.5 to 2.5% RSD for the 3-ppm level. In sum, we observed excellent performance for both concentration and retention time repeatability. Figure 4 depicts an overlay of five consecutive runs for hydrogen sulfide at the 10-ppm level.

Fast, accurate gas analyses in remote locations

The new sample inlet design for the Agilent 490 Micro GC, with Agilent proprietary UltiMetal treatment for stainless steel surface deactivation, provides accurate analyses of low-ppm-level sulfur compounds. The Agilent 490 Micro GC with the Agilent J&W PoraPLOT U column channel simplifies analysis of hydrogen sulfide and carbonyl sulfide down to the 3-ppm level with excellent concentration and retention time repeatability. For full details about this study, download Agilent Application Note 5991-6241EN.

With its speed of analysis, the Agilent 490 Micro GC provides reliable results quickly for better and faster product and process quality control. Discover more today about the Agilent 490 Micro GC.

References

- Fast and Reliable Trace Gas Analysis—Improved Detection Limits for the Agilent 490 Micro GC, 5991-6201EN (2015).

- Agilent 490 Micro GC Solution, 5991-6034EN (2015).

- Analysis of Biogas Using the Agilent 490 Micro GC Biogas Analyzer, 5990-9508EN (2011).

- Fast Analysis of Natural Gas using the Agilent 490 Micro GC Natural Gas Analyzer, 5991-0275EN (2012).

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – April 2016

All articles in this issue

-

Analyze low-ppm levels of active sulfur compounds with inert sample path on the Agilent 490 Micro GC

Analyze low-ppm levels of active sulfur compounds with inert sample path on the Agilent 490 Micro GC -

Fast arsenic speciation for food and urine analysis with Agilent LC-ICP-QQQ

Fast arsenic speciation for food and urine analysis with Agilent LC-ICP-QQQ -

Simplify achiral-chiral analysis of warfarin metabolites using Agilent 2D-LC/MS solutions

Simplify achiral-chiral analysis of warfarin metabolites using Agilent 2D-LC/MS solutions -

Optimized detection of gaseous sulfur compounds using Agilent J&W DB-Sulfur SCD GC column and Inert Flow Path

Optimized detection of gaseous sulfur compounds using Agilent J&W DB-Sulfur SCD GC column and Inert Flow Path -

Oil-free laboratory vacuum eliminates oil mess and disposal costs

Oil-free laboratory vacuum eliminates oil mess and disposal costs -

Eliminate conventional SEC roadblocks with Agilent AdvanceBio SEC columns

Eliminate conventional SEC roadblocks with Agilent AdvanceBio SEC columns -

Fast, economical assessment of herbals with Agilent 1290 Infinity LC system and LC columns

Fast, economical assessment of herbals with Agilent 1290 Infinity LC system and LC columns -

Agilent 5977B GC/MSD with HES offers improved VOC detection limits

Agilent 5977B GC/MSD with HES offers improved VOC detection limits

Figure 1

The updated sample inlet design for the Agilent 490 Micro GC reduces surface activity and minimizes the potential for leaks.

Figure 2

Trouble-free separation of hydrogen sulfide and carbonyl sulfide from the other compounds in biogas and natural gas on the Agilent J&W PoraPLOT U column channel.

Figure 3

Successful analysis of 3 ppm hydrogen sulfide and carbonyl sulfide on the Agilent 490 Micro GC with inert sample path.

Figure 4

Repeatable analyses: overlay of five replicate runs for 10 ppm hydrogen sulfide.