Key Takeaways

- A more efficient lab is a more sustainable one – Lab optimization is essential

- Lab leaders want to improve both efficiency and sustainability

- Expert guidance and data intelligence can achieve both goals

The average lab consumes more energy per square foot than many hospitals or other commercial buildings—the EPA estimates that a 30 percent reduction in lab energy use translates to removing 1.3 million cars from highways per year—yet lab optimization is often not a priority. 1, 2, 3

With labs experiencing an ever-increasing demand for greater efficiency and productivity as well as a strong desire to maximize sustainability, from the organization-wide level to daily operations, lab optimization presents a path forward. Combining new data intelligence technologies with better industry insight guidance allows for advancing lab operational efficiency through better asset utilization and increased sustainability in the digital lab era.

Lab managers want sustainability and optimization

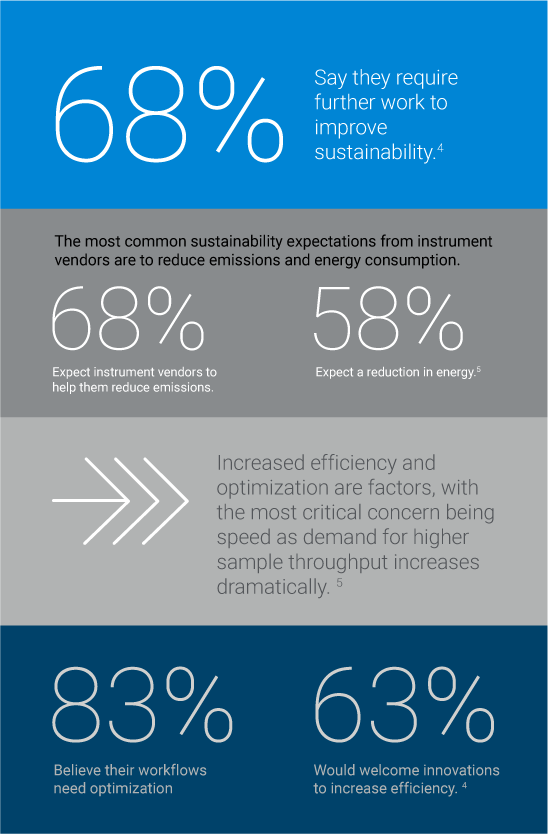

The central premise for discussing sustainability and optimization together is that a more efficient lab is a more sustainable one. Most lab managers are mindful of both sustainability and optimization needs. A global survey of lab managers highlighted a strong desire to meet sustainability goals and remain conscious of sustainability in their daily operations.

Lab managers in their own words:

Advanced asset control, digital analytics, and expert guidance

The opportunity for lab optimization improvement is profound. On average, lab instruments are running only 35 percent of the time, and only four percent of labs employ data intelligence to ascertain fleet utilization. 6

A holistic method of assuring lab-wide optimization and efficiency is required to address this gap effectively. A combination of advanced asset control, digital analytics, and expert guidance allows greater visibility and utilization of all lab assets. Maximizing the availability and utilization of all assets will reduce a lab’s carbon footprint and enable more science to be done. Increasing operational efficiency and productivity positively impacts lab sustainability. Reducing energy consumption through increased efficiency is a win-win, especially for the environment.

James Connelly, chief executive officer of My Green Lab agrees, "Lab equipment makes up a significant portion of the total plug load in any lab and can lead to high energy consumption. Optimization of lab equipment through solutions such as asset performance management can dramatically lower the overall energy consumption and be a significant step toward achieving lab sustainability.”

Data intelligence and expert guidance

Data intelligence systems with real-time sensing technology and interconnectivity provide better visibility into lab operations and help drive decisions. Gaining clarity on asset utilization enables more informed decision making that advances lab operations to new levels of efficiency and productivity—while increasing sustainability at the same time. Measuring asset utilization opens the door to appropriate fleet right-sizing and technology refresh, resulting in higher throughput, less power consumption, a smaller workflow footprint, and redeployment of under-used or redundant instruments.

Using real-time digital data regarding lab instrument health and utilization, combined with expert analysis, provides a performance profile of critical lab assets and lab function. This gives lab managers information to move beyond reactive, time-consuming lab operation reviews to proactively address lab performance and strategically plan more efficient, fit-for-purpose operations. Managing assets through the lens of lab performance affords the ability to proactively adjust to changing business conditions and grow lab operations in an organized manner, ensuring optimal performance throughout all stages of development.

Data intelligence helps determine how to best evolve lab facilities to meet changing conditions without negative impacts. It is also a prerequisite for successfully advancing lab operations when combined with expert guidance. For example, lab-wide asset monitoring of equipment provides a comprehensive view of instrumentation at all times, ensuring maximum utilization and enabling greater understanding and control over assets. Expert guidance can assist with proper integration and interpretation of asset utilization data. Careful analysis of instrument utilization provides the basis for data-driven decisions, giving insight into fleet right-sizing and balancing scientific assets.

Go greener with asset monitoring

The process of lab optimization involves integrating utilization data with instrument service histories and end-of-guaranteed support to measure the instrument health. Understanding instrument utilization and health can determine the optimal footprint and workflow composition.