Collaboration Goes with the Flow

|

|

November 4, 2004

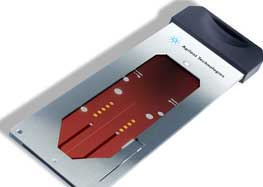

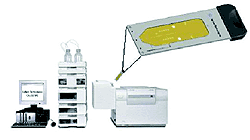

Multi-disciplinary teamwork within Agilent Technologies pays off with a new approach in microfluidics that promises to help scientists gain greater insights in the growing field of proteomics. Until now, when scientists worked in critical areas like protein research and pharmaceutical development, they often had to rely on equipment that was labor-intensive or difficult to set up and operate. Researchers, however, can now look forward to a new system from Agilent Technologies that offers greater accuracy and ease of use when performing proteomic analysis-and hopefully, will advance important research that will help arm researchers with new knowledge and effective drugs to battle some of today's most challenging diseases. Through an extensive, decade-long development effort that began as a low-key technology investigation in Agilent Laboratories, the new HPLC-Chip/MS will soon be available to biological and chemical researchers dissecting the micro-scale world of proteins known as proteomics. It's in this area of research that inroads are being made -- in part due to strides made in genomics and the mapping of the human genome -- in understanding the important role that proteins in cell structures play in our overall health. The new system from Agilent is a breakthrough microfluidics-based technology for liquid chromatography (LC) and mass spectrometry (MS), which is used by scientists in protein research and pharmaceutical applications to separate and identify biological compounds. The centerpiece of the new technology is a reusable polymer high-performance HPLC chip, which offers new levels of ease of use, sensitivity and reliability. Smaller than a credit card, the new HPLC chip seamlessly integrates the sample enrichment and separation capability of a nanoflow LC system with the intricate connections and spray tips used in electrospray mass spectrometry.

None of this would be possible, however, without the stellar collaboration of a diverse, multi-disciplinary team of engineers and scientists within Agilent and Agilent Labs. Referred to as an "extreme" collaboration, the project brought together four separate groups, including research teams in Agilent Labs' life sciences and electronics organizations, with a wide range of researchers all with unique skill sets expertise and perspective. "I don't think this project could have happened anywhere but at Agilent," says Georges Gauthier, a product manager for the Pharmaceutical Solutions Business Unit. "The investigative freedom provided to researchers in Agilent Labs, combined with the company's unique understanding of the life science marketplace and its chip-design knowledge, has made the HPLC-Chip the groundbreaking product it is today. No one else could have brought all these elements together." Early Investigation While early experiments included using microfluidic channels to electrophoretically separate chemical compounds on a chip, Agilent Labs' researchers were given leeway to experiment in a variety of areas. Important progress was made, especially in the area of laser ablation, which uses the same low-cost polymer --polyimide --used in HP inkjet print heads. One of the first groups involved in the research was Agilent Labs' life science lab. Among other things, it was focused on advancing microfluidic applications using liquid-phase separation in combination with mass spectrometry to create an advanced way of performing chemical separation and (protein) identification. This method was a dramatic change from today's more conventional approaches, such as two-dimensional (2-D) gel electrophoresis followed by mass spectrometry to detect proteins. "Researchers have been looking for alternatives to the labor-intense and time-consuming procedures currently used for identification of proteins," says Tom van de Goor, a project manager in Agilent's life science division. "Combining liquid chromatography with mass spectrometry is one of the big drivers in proteomics right now because of the advantages of automation." The team hoped to design a microfluidic chip that would perform the equivalent of 2-D analysis, but with greater ease of use and reliability. With that end in mind, they turned to colleagues in Agilent Labs' electronic research lab for help in processing and characterizing a specialized chip. Still, a host of technological challenges lay ahead.

A Cut Above The superior properties of polyimide film made it ideal for use in microfluidic devices because it is compatible with most organic solvents and responded well to heat and pressure to form a laminated all-polyimide device. It was a key decision in helping create a chip with integrated functionalities. The Labs team experimented with high-pressure separation using LC on the chip to improve protein analysis beyond capillary electrophoresis, which uses electricity to separate compounds. This feature helps to differentiate the chip in the proteomics marketplace. One of the biggest challenges, and subsequently, one of the biggest milestones for the project, was finding a way to cut an electrospray tip into the chip itself. The electrospray tip is a needle-shaped feature at the end of the channel of the chip that, when voltage is applied between it and the mass spectrometer, ionizes material by turning the liquid into gaseous ions. These ions in turn can be analyzed by the mass spectrometer. However, building a three-dimensional structure on a laminated chip around miniscule channels only 10 microns to 30 microns in size was a daunting task. Agilent Labs researcher Kevin Killeen faced the challenge and successfully developed a conical-shaped electrospray tip integrated on the chip Going to Market

Today, all of the groups involved have collaborated successfully to transfer the polymer-laser ablation fabrication technology to LSCA's Waldbronn Analytical Division, where the HPLC chips will be manufactured. Final field tests are underway with customers and after incorporating final changes in software and the MS interface for the chip, the new system will be ready for market. Notes scientist van de Goor: "Even after all the years of working on this technology, there is still a lot of excitement in seeing it move into the marketplace." Related Information |