Digital Lab

CrossLab Enterprise Services

A Learning Café

for the Enterprising Lab

Advance operations across your organization

If you have a centralized lab or shared facilities, Agilent CrossLab Enterprise Services can give you insights into improving efficiency, optimizing resources, and increasing instrument uptime. Our asset management, compliance, operational, and digital services work together to simplify, optimize, and transform your lab operations.

Is it time for your lab to embrace the digital transformation?

If you’re responsible for a laboratory, you understand the effort it takes to make confident, data-driven decisions—and to remain competitive in a complicated, changing landscape.

The keys: efficiency and data visibility. Together, these give your lab the capacity to meet challenges and changes by ensuring that your operations are optimized and that the right equipment is available when needed. What’s more, building visibility and efficiency will enable you to benchmark, modify, and improve your operations, paving the way for business transformation.

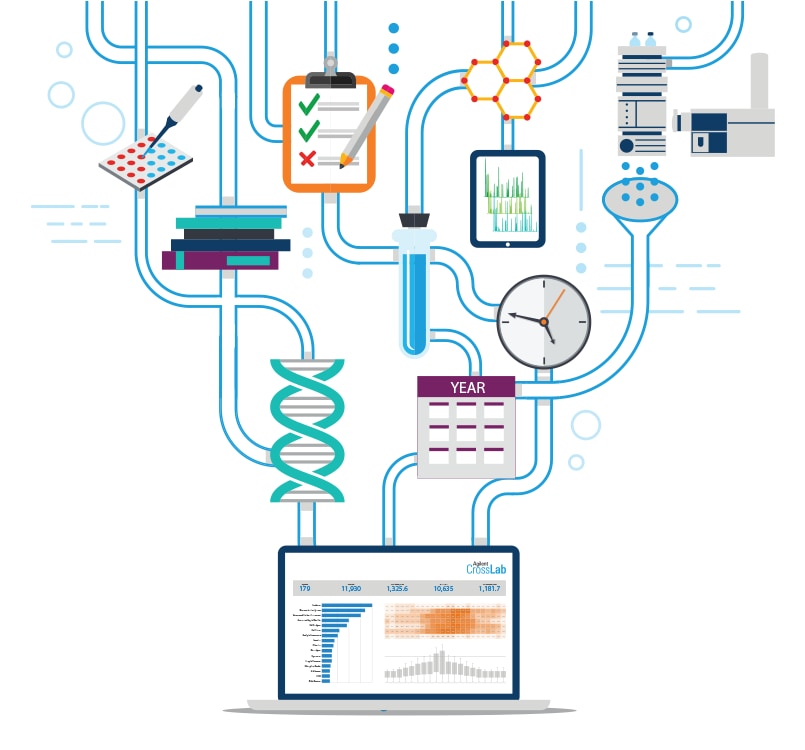

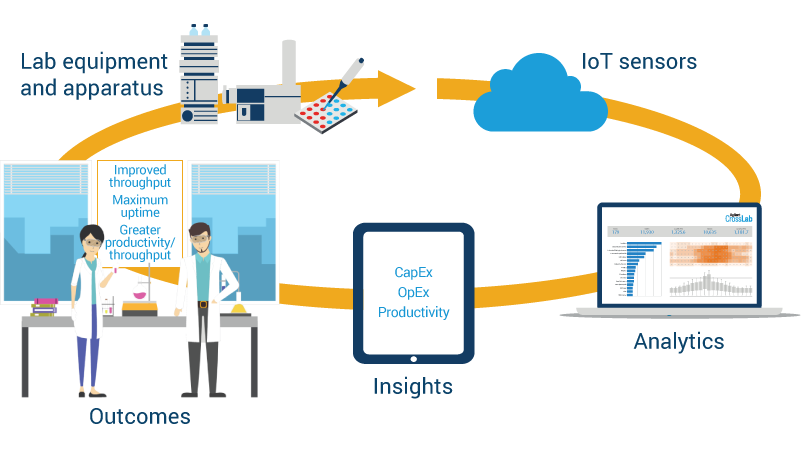

What’s the hallmark of a digital lab? The digital lab includes strategies to leverage smart systems, connected devices, cloud capabilities and Internet of Things (IoT) technologies that are capable of collecting vast amounts of data. By relying on these capabilities, you can improve your capital expense planning, reduce operating costs, receive critical instrument notifications, and increase your throughput.

Data, data everywhere

Throughout any instrument life cycle, many points of data are collected about operations, usage, service history, and other critical functions. But it’s not always easy to capture lab-wide instrument data across all your workflows. For example:

- Spreadsheets and manual data collection are time-consuming and inconsistent.

- Instruments from different manufacturers don’t always measure the same way, so data normalization is needed for useful analytics and organizational acceptance.

- Analytics depend upon the person performing the analysis and their consistency over longer periods of time.

- Gathered data do not always reflect your complete workflow.

Moving toward a digitally connected,

consistently measured lab

Simply put, the digital lab embraces smart technologies that are connected and capable of collecting vast amounts of data—and helping you transform data into insights.

Evolving into a smart, connected lab can improve capital expense planning, reduce operating expenses, and improve throughput. All without compromising your results, budget, or lab space.

Are you just gathering data or building insights?

The operational data collected from your instruments is a valuable tool for improving performance and efficiency. But only if you aggregate and analyze that data in a way that lets you make operational adjustments that result in measurable outcomes.

You’ve collected your data…what happens next?

Once assembled, data must be normalized and analyzed with tools fit for improving lab operations. Laboratories often use spreadsheets and logs for this purpose, but these tools are designed for viewing data rather than creating understanding. The result: inconsistent interpretation and internal challenges to the validity of the data.

What’s more, with noncentralized data gathering and analysis, there is often a responsibility vacuum for follow-through. So, even if you did identify opportunities for optimization, implementing these changes would become an added burden to managers with an already full workload.

Resources

How do fact-based insights help you advance your lab?

At its heart, the digital lab enables transformational outcomes through a single source of truth. By combining the Internet of Things (IoT) with data analytics capabilities, your lab can capture data, create business intelligence, and implement actioned programs.

Managing your digital lab transformation

At the highest levels, many labs have the same strategic goals and compete in markets with common drivers. But underneath, each lab strives to achieve these goals differently, with the intent of becoming the market leader.

Your digital lab transformation should convey the following elements to your lab teams: data architecture, data consumption, and long-term objectives for data use. Once understood by everyone, your digital tools will provide the infrastructure to uncover opportunities and spark further innovation.

Carefully choosing—and collaborating—with a vendor can help you define the steps needed to achieve that aim.

The digital lab: Real stories, real results

Compliant, standardized, visibility

Big pharma R&D site

- 26% redux contract costs

- $400K CapEx avoidance

- 300+ hours saved

Optimal, available, purpose driven

Midsized biotech QC lab

- $68k OpEx reduction

- $250k CapEx avoidance

- $26k Resale

Prioritize, prepare, advance to the next level

Sterile manufacturing facility

- Reduce maint. disruptions

- Up to 59% redux power cold storage

- $76k CapEx avoidance

Is your lab ready to begin its digital transformation?

Better capital expense planning. Lower operating costs. Critical instrument notifications. Increased throughput. Making the digital transformation enables your lab to achieve all of these goals.

Using IoT sensor technologies, AI modeling, and advanced analytics, your digital lab can safely capture data, create business intelligence, and implement actioned programs. Ready to move ahead? Here are some key considerations.

CrossLab Asset Monitoring

Collaborate for success

Part of your digital lab journey involves recognizing the importance of the consultative process and the change management that your organization may require.

Careful consideration should be taken when choosing a vendor. That’s because a truly collaborative program starts with fully defining your goals—and the steps toward achieving them—through consultative engagement with your team. Your goals should also include understanding the insights created through data analytics, defining actions against insights, and driving actionable programs to realize the desired benefits.

What you will end up with is a single source of truth that steers transformational outcomes.

Paths forward

Two ways that Agilent is providing digital tools to laboratories include CrossLab Smart Alerts and CrossLab Asset Monitoring, part of the CrossLab Connect portfolio.

If you desire deeper insights into your Agilent instruments, CrossLab Smart Alerts allows you to:

- Get an immediate view into the operational status of equipment across your lab.

- Be alerted to the need for critical operator maintenance, enabling you to maximize uptime and sustain instrument performance.

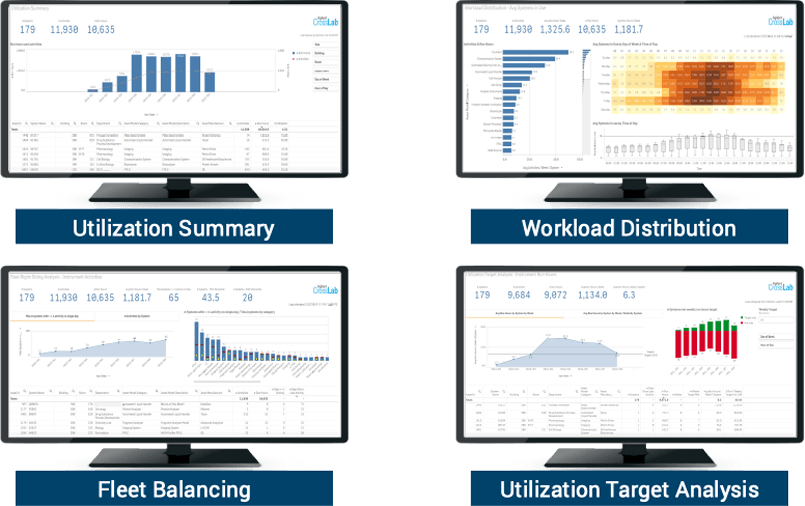

Need insights into all instruments across your laboratory? CrossLab Asset Monitoring measures how your lab utilizes instruments of any type, manufacturer, or software. It combines Agilent sensors with artificial intelligence (AI) to ensure monitoring breadth and reporting accuracy. This equips you to make confident, data-driven decisions.

CrossLab Asset Monitoring allows you to receive instrument utilization data to:

- Drive capital planning and technology refresh cycles.

- Build a clear line of sight into your asset productivity.

- Optimize operational spending.

The ongoing consultation included with these programs ensures that you receive the knowledge and expertise gained from hundreds of similar engagements by Agilent Enterprise Teams worldwide.