Agilent High-Temperature GC Columns

When the Heat Is On,

Will Your GC Supplies Deliver?

Agilent J&W high-temperature GC columns and supplies

New study reveals which GC columns can withstand temperatures of 400 °C for extended periods of time

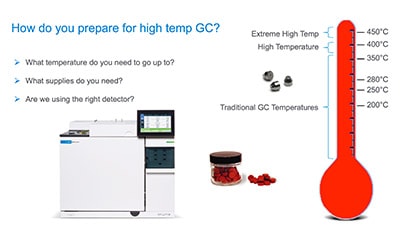

Traditional GC columns are made from fused silica with a polyimide outer coating, which is ideal for most applications. However, temperatures above 360 °C degrade this coating and reduce the physical strength of the column—making it susceptible to breakage.

Agilent J&W high-temperature GC columns feature a high-temperature polyimide that can operate in temperatures of up to 400 °C. They combine robustness with advanced surface deactivation for improved column lifetime and peak shape. In addition, they feature advanced stationary phase bonding for low bleed performance at high temperatures.

What about applications operating higher than 400 °C?

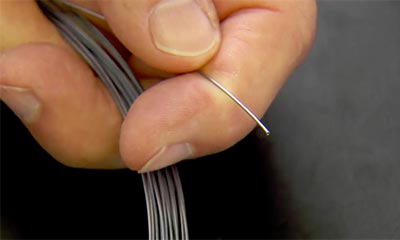

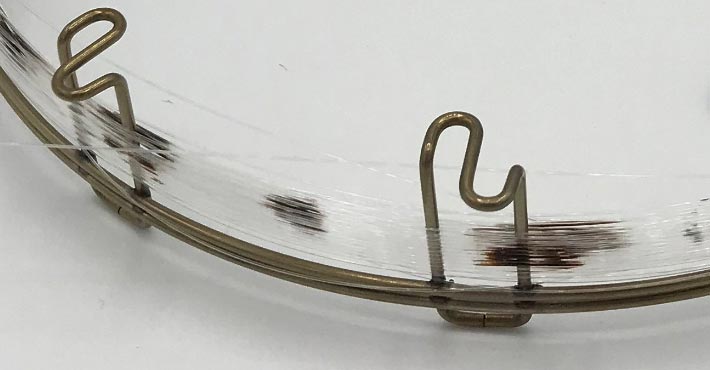

For applications above 400 °C, metal GC columns offer better durability and ruggedness than fused silica tubing. Agilent J&W UltiMetal and DB-ProSteel deactivated stainless steel GC columns last long even under extreme conditions.

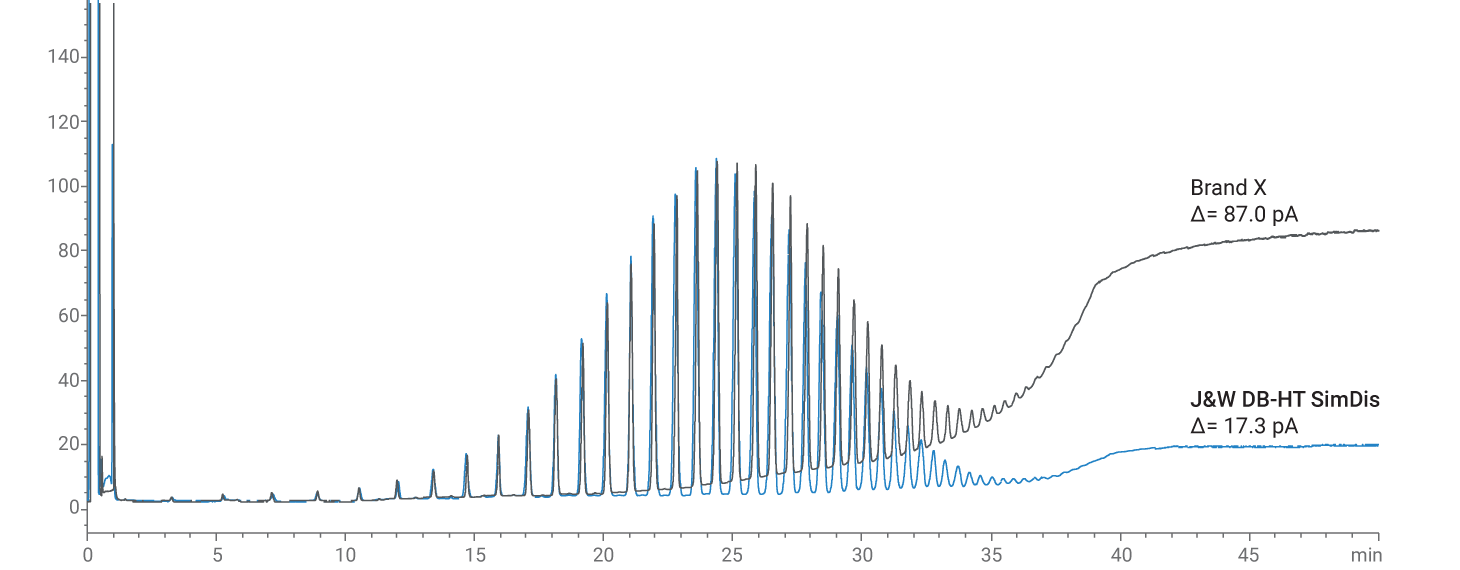

We wanted to see which columns withstood high temperatures best.

So, we put them to the test.

In our study, we compared Agilent high-temperature GC columns with columns from different suppliers.

Here’s what we found:

Agilent CrossLab services. From insight to outcome.

CrossLab is an Agilent capability that integrates services and consumables to support workflow success and important outcomes like improved productivity and operational efficiency. Through CrossLab, Agilent strives to provide insight in every interaction to help you achieve your goals. CrossLab offers method optimization, flexible service plans, and training for all skill levels. We have many other products and services to help you manage your instruments and your lab for best performance.

Learn more about Agilent CrossLab, and see examples of insight that leads to great outcomes.