Access Agilent eNewsletter, May 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Using Agilent dual-column GC to assess the value of natural gas liquids

By Brandt Hutchison

Mid-America Pipeline Co.

Wayne Collins

Agilent Global Energy & Chemicals Marketing Manager

Global demand for clean energy has increased the need for efficient natural gas exploration and production. Natural gas is a naturally occurring mixture of gaseous hydrocarbons that consists primarily of methane. However, natural gas can also contain a significant amount of ethane, propane, butane, pentane, and other heavier hydrocarbons that must be removed prior to the methane being sold for commercial use. These heavier grade hydrocarbons removed from natural gas are known as natural gas liquids (NGLs) or Y-grade.

Y-grade natural gas is typically transferred by pipeline to a centralized storage facility to await fractionation at a later date. Agilent Natural Gas Analyzers offer a range of solutions for laboratories that analyze these natural gas liquids from the pipeline and issue certificates of analysis that are used to determine the market value of the product.

The value of extended analysis is to better characterize the sample for determination of maximum market value that can be derived from the particular mixture. Y-grade is not traded as a product but is fractionated into five pure products that are globally traded every day. The products are ethane, propane, n-butane, isobutane, and the heavier fraction known as natural gasoline. Each of the component fractions has different physical characteristics, different end-use markets, and most importantly, different factors that make prices rise and fall. The value of the Y-grade is determined by the quantities and characteristics of these five products, which can be produced from the particular batch.

The Gas Processors Association (GPA) publishes several standard methods for the analysis of natural gas and natural gas liquids. The GPA 2186-02 method can be performed on two separate gas chromatographs but is more typically done on a single chromatograph with two channels. This method uses a packed column and a capillary column for the separations.

Different columns and different detectors

Enlarge

Enlarge

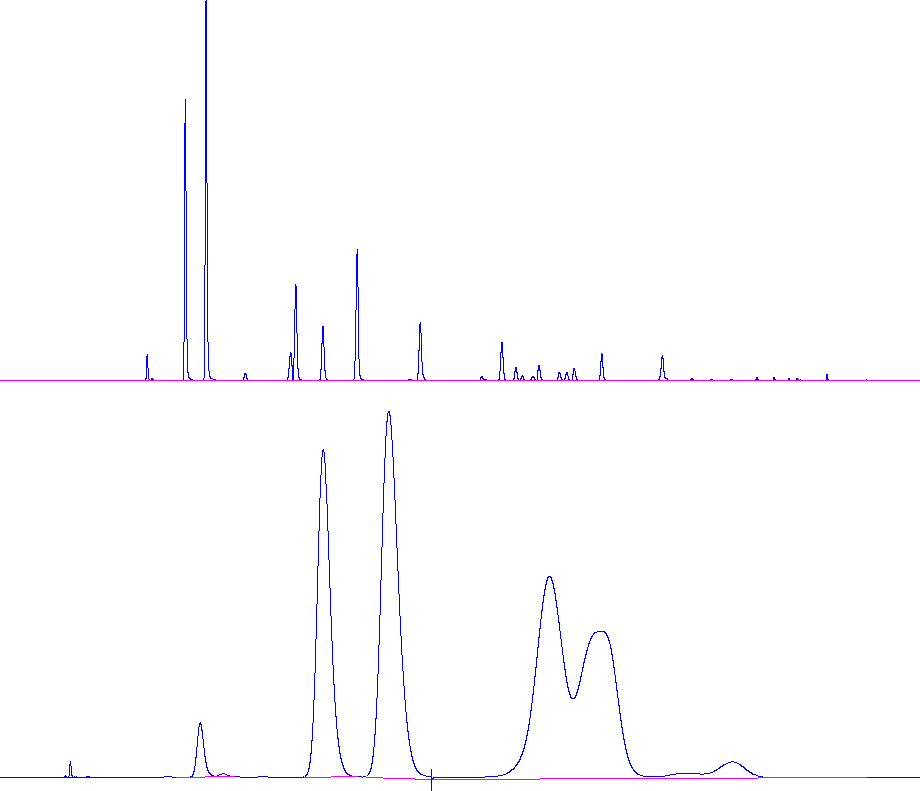

Figure 1. Example of a typical Y-grade sample chromatogram; hydrocarbons (above) and permanent gases (below).

In brief, the sample is analyzed in parallel with simultaneous injection onto both columns. Nitrogen/carbon dioxide through n-pentane are separated isothermally on the packed column and detected with a thermal conductivity detector, while the C6+ hydrocarbons are separated on the capillary column and detected with a flame ionization detector. The resulting chromatograms are used to calculate the weight percent, mole percent, and liquid volume percent of each component. The n-pentane peaks from each chromatogram are used to bridge weight percentages to combine results from both chromatograms into a single report. Chromatographic results are then normalized and summed. Customers expect the total of all reported components to sum to exactly 100%, so any residual due to rounding in the calculations is either added to or subtracted from the largest component percentage to accomplish this.

Figure 1 is an example of a typical Y-grade sample chromatogram with all of the peaks properly identified. The analysis was accomplished using a dual-channel Agilent 7890 GC equipped with a capillary Agilent J&W CP-Sil 5 CB GC column.

Detailed characterization

Although GPA 2186 is a relatively complex method, it provides a detailed characterization of NGLs to insure that natural gas companies obtain fair value for their products. However, the improved characterization of the mixture comes at a price. The calibration procedure is very complicated and sometimes requires a day or more to complete. Part of the problem is that the calibration mixture contains only 62 compounds while the method analyzes for 157. A more complete calibration mixture would help in removing the uncertainty, especially in identification of compounds and setting retention times. High Y-grade samples used to fill in retention times for compounds missing from the calibration mixture may not have all of the compounds present in sufficient quantity to accurately identify each peak. Luckily, these compounds are always very minor constituents, and so small errors in identification and quantitation do not significantly affect the result or value of the product.

Once the initial calibration is completed, it remains stable over a long period of time, reducing the calibration frequency per company standard operating procedure. Periodic checks are used to confirm that the calibration remains valid. Automation is essential for running this method in a production environment. Agilent Natural Gas Analyzers automatically perform all calculations and generate finished reports. Complexity of the method is removed so that you simply load the sample and start the run. This allows fast turnaround of samples, eliminates calculation errors, and simplifies training requirements.

You will find full details of this analysis in our new Application Note on Analysis of Gas Liquids by GPA 2186.

Agilent energy solutions maximize energy value

This solution is just one among many offered by Agilent for natural gas characterization, essential to maximize the commercial value of this natural resource. Learn how Agilent Natural Gas Analyzers can help you develop workflows that produce accurate, reliable data, and ensure the best product quality. Then explore more options at Agilent Natural Gas Solutions.

>> Update My Profile | Subscribe to Access Agilent | Article Directory