Access Agilent eNewsletter September 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Precise quantitative analysis of trace elements in high purity copper using laser ablation-ICP-MS

By Naoki Sugiyama

Agilent ICP-MS Product Manager

and Mineko Omori

Agilent ICP-MS Applications Specialist

From geological sample types and ceramics to biological tissue and forensic samples, laser ablation-ICP-MS (LA-ICP-MS) is used for the elemental analysis of solid samples and pressed powders; however, calibration can be problematic for LA-ICP-MS analysis because of the lack of solid standards to permit accurate quantitative analysis. Preparing calibration standards for the analysis of solids is more difficult than it is for liquid sample analysis, and matrix-matched solid calibration standards are rarely available.

An alternative approach is to calibrate using existing solid Certified Reference Materials (CRMs) of a different composition, that is, non-matrix matched standards. Yet ablation yield and elemental fractionation during the ablation process may differ between the CRM and the sample, causing significant error in quantification. In a few cases, such as the metals industry, well-characterized, matrix-matched standards may already be available, since established analytical techniques such as Arc/Spark or Glow Discharge (GD) Optical Emission Spectroscopy (OES) already require solid standards. In this work, we report accurate and precise quantitative LA-ICP-MS data for trace elements in high purity copper, using certified copper standards for calibration.

Simplified operation with plug-in module for ICP-MS MassHunter

In our analysis, a NWR231 (ESI, California, USA) deep UV Nd:YAG laser having a wavelength of 213 nm and pulse duration time of 4 ns was coupled with an Agilent 7900 ICP-MS. The Agilent 7900 ICP-MS was operated in hydrogen mode to remove matrix argide interferences such as ArAr+, ArO+ and CuAr+, which are more problematic for laser ablation (dry plasma) than the oxide interferences typically encountered in solution mode.

Using the MassHunter plug-in developed by ESI, the LA system was controlled directly from the Agilent ICP-MS MassHunter 4.2 software for fully integrated sample analysis. The scan-pattern was set up in the LA system and then loaded into MassHunter where the run was controlled using the plug-in software. NIST 612 Trace Elements in Glass was used to tune and calibrate the LA-ICP-MS system. LA-ICP-MS operating conditions are given in Table 1.

ICP-MS parameter |

Unit |

Value |

|---|---|---|

RF power |

W |

1550 |

Sampling depth |

mm |

8 |

Carrier gas flow rate |

L/min |

1.15 |

He (laser) gas flow rate |

L/min |

0.8 |

Extraction 1 lens |

V |

-15 |

Extraction 2 lens |

V |

-180 |

KED |

V |

3 |

H2 cell gas flow rate |

mL/min |

3.8 |

Data acquisition mode |

|

spectrum |

Integration time |

s/mass |

1 |

Number of sweeps |

|

50 |

Scan lines |

|

5 |

Replicates per scan line |

|

3 |

LA parameter |

Unit |

Value |

Fluence |

J/cm2 |

3 |

Spot size |

µm |

200 |

Scan pattern |

|

line |

Scan rate |

µm/s |

10 |

Pre-ablation |

|

on |

Warm-up time |

s |

10 |

On delay time |

s |

20 |

Table 1. LA-ICP-MS operating parameters.

Enlarge

Enlarge

Figure 1. Matrix-matched calibration curves for As, Se and Ag using copper matrix standards.

Enlarge

Enlarge

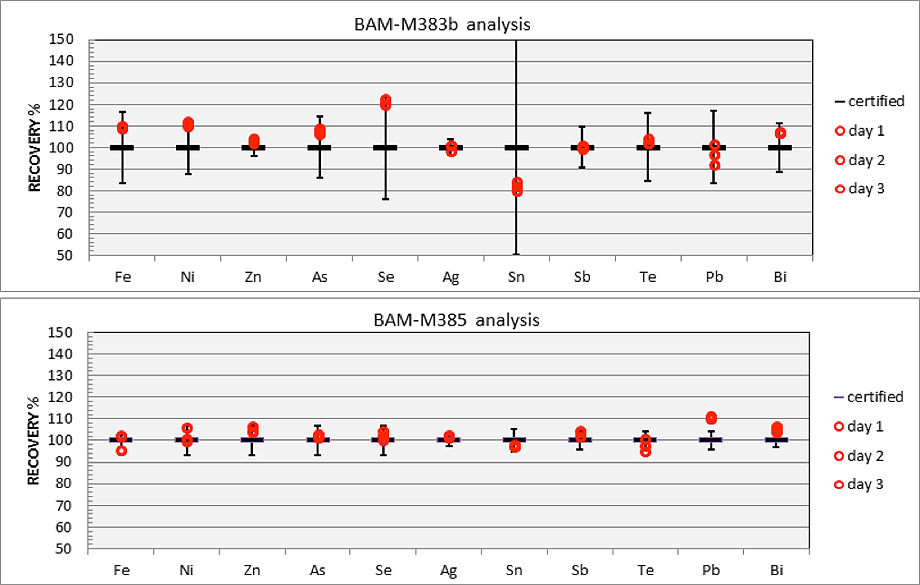

Figure 2. Recovery of selected elements on three different days.

Accurate results with matrix-matched calibration

In our example, two copper CRMs (BAM-M385 and BAM-M383b), were analyzed as unknown samples using spiked solid copper standards as a matrix-matched calibration. Four COPPERSPEC standards, 001, 005, 030, and 100, spiked with 11 elements at 0.1, 0.5, 3, and 10 ppm respectively, were used for the calibration. 65Cu was used as internal standard (ISTD) to correct for any variation in the LA system, ablation yield, and signal suppression/drift of the ICP-MS. Representative calibration curves for three elements (As, Se, and Ag) demonstrated good linearity, as shown in Figure 1.

Table 2 shows the measured results (average ± standard deviation of five separate ablation lines) and certified concentrations for 11 elements in the two copper CRMs. The measured concentrations are in good agreement with the certified values; all within ± 10% deviation or uncertainty (given error range) of the CRMs.

The same analysis was repeated on three different days, with good reproducibility. Figure 2 shows the percent recovery of the measured average concentrations compared to the certified value on the three days. The results for BAM-M383b have higher variability due to the much lower concentrations of trace elements in this CRM (single- or sub-mg/kg for most elements), but the data show that the LA-ICP-MS method is suitable for quantitative analysis of trace elements at the low ppm level in solid copper, with accuracy typically better than ± 10%.

BAM-M383b |

BAM-M385 |

|||

|---|---|---|---|---|

Element |

Certified mg/kg |

Measured mg/kg |

Certified mg/kg |

Measured mg/kg |

Fe |

3.60 ± 0.60 |

3.92 ± 0.13 |

45.4 ± 1.4 |

43.5 ± 0.1 |

Ni |

1.43 ± 0.18 |

1.59 ± 0.02 |

11.9 ± 0.8 |

12.0 ± 0.1 |

Zn |

9.30 ± 0.40 |

9.69 ± 0.15 |

57.9 ± 4.0 |

61.6 ± 0.4 |

As |

2.80 ± 0.40 |

3.05 ± 0.16 |

11.4 ± 0.8 |

11.7 ± 0.3 |

Se |

1.17 ± 0.28 |

1.43 ± 0.13 |

7.20 ± 0.50 |

7.37 ± 0.64 |

Ag |

10.60 ± 0.40 |

10.72 ± 0.36 |

28.6 ± 0.8 |

29.2 ± 0.4 |

Sn |

0.80 ± 0.40 |

0.66 ± 0.04 |

18.0 ± 0.9 |

17.6 ± 0.5 |

Sb |

1.69 ± 0.16 |

1.71 ± 0.13 |

19.9 ± 0.8 |

20.8 ± 0.6 |

Te |

5.70 ± 0.90 |

5.94 ± 0.69 |

10.0 ± 0.4 |

10.1 ± 0.4 |

Pb |

1.01 ± 0.17 |

1.03 ± 0.09 |

11.3 ± 0.5 |

12.6 ± 0.4 |

Bi |

1.85 ± 0.21 |

1.98 ± 0.21 |

5.81 ± 0.17 |

6.18 ± 0.22 |

Table 2. Measured (average of 5 ablation lines) and certified concentrations of representative elements in two copper CRMs: BAM-M383b and BAM-M385.

Accurate analysis using non–matrix matched calibration

As demonstrated in this work, the use of matrix-matched copper calibration standards allowed accurate analysis of trace elements in copper CRMs within ± 10% of the certified values. However, in many applications of LA-ICP-MS, known or certified standards are not available and cannot easily be made. In these cases, non–matrix matched calibration can be used, based on a common, commercially available, and well-characterized CRM, such as NIST 612 Trace Elements in Glass. For details on accuracy achieved using this non–matrix matched approach and to learn more about the Agilent 7900 ICP-MS for laser ablation, see Agilent publication 5991-6156EN.

Agilent ICP-MS Journal

Are you interested in trace metals analysis and eager to keep up-to-date with the latest developments in the field of ICP-MS? Then we invite you to take a closer look at Agilent’s dedicated ICP-MS Journal. Published four times a year and available as a PDF, you can view the latest issue of the ICP-MS Journal, plus all previous copies, by visiting the ICP-MS Journal Archive.

To receive a personal copy of the ICP-MS Journal direct to your inbox, please sign up here.

>> Update My Profile | Subscribe to Access Agilent | Article Directory