Access Agilent eNewsletter September 2015

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Quick, easy analysis of food preservatives with Agilent 1290 Infinity II Multisampler

By Sonja Schneider, Melanie Metzlaff

Agilent Application Scientists

Over the past few decades, there has been a steady and increasing demand for rapid food screening to ensure food safety. Preventing people from exposure to potentially harmful contamination from phthalates found in drinks, food, or rotten meat is a challenge. Conventional high performance liquid chromatography (HPLC) methods are routinely used for food monitoring as one of the most reliable and rugged analysis techniques.

The new possibilities of UHPLC systems with sub-2 µm (STM) particle columns allow ultrafast separations at quicker than one minute run times. Typically, a UHPLC cycle time consists of sample injection, gradient, column wash, and equilibration. Duration of total cycle time can be reduced by using automated column regeneration – saving the column wash and equilibration time. Automated column regeneration uses a setup of two pumps, which allows the regeneration of the first column, while the compounds are analyzed by the second column, and vice versa.

Enlarge

Enlarge

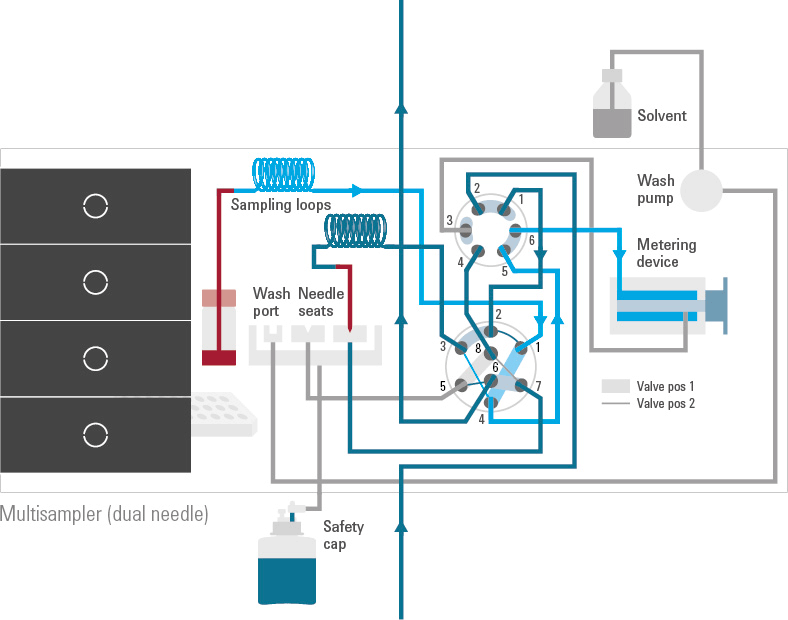

Figure 1. Hydraulic concept of the 1290 Infinity II Multisampler.

Dual-needle option on Agilent 1290 Infinity II LC offers higher throughputs

To address the increasing demand for quicker analysis times, a second injection needle installed in the new Agilent 1290 Infinity II Multisampler with dual-needle option offers a significant reduction in analysis time. This allows simultaneous analysis on the first flow path and overlapped sample draw using the second flow path preparing the next run, called “Smart Overlap."

Figure 1 shows the hydraulic concept of the Agilent 1290 Infinity II Multisampler. To illustrate, ultrafast analysis of food preservatives optimized for high-throughput analysis is shown. Using alternating column regeneration in combination with parallel injection with a second needle installed in the new Agilent 1290 Infinity II Multisampler demonstrates the enormous time-savings realized by using the “Smart-Overlap” and column regeneration function.

Enlarge

Enlarge

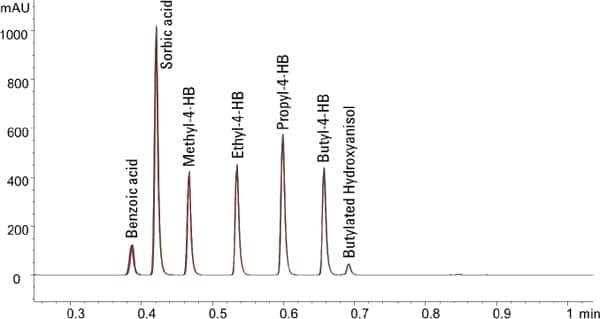

Figure 2. Overlay of 14 subsequent runs of the preservatives separation with dual-needle setup and automated column regeneration.

Alternating column regeneration and parallel injection deliver over 60% reduction in cycle times

To demonstrate the speed and robustness of the dual-needle setup, a preservative standard with seven different compounds was used. For the analysis, an Agilent 1290 Infinity II LC system was used to perform the column equilibration in parallel with the run. Two identical columns and a second pump were used for comparison.

Retention time and area precision were tested for every individual needle (intra-needle precision), for a combination of both needles (inter-needle precision), as well as for the complete setup including automated column regeneration using two columns in an alternating way. Figure 2 shows an overlay of 14 subsequent runs of the separation of the preservative standards, indicating excellent retention time (RT) precision.

|

|

Column 1, Needle 1 |

Column 1, Needle 2 |

Column 1, Dual Needle |

Column 2, Dual Needle |

Dual-needle automated column regeneration |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Substance |

RT [min] |

RSD RT [%] |

RSD Area [%] |

RSD RT [%] |

RSD Area [%] |

RSD RT [%] |

RSD Area [%] |

RSD RT [%] |

RSD Area [%] |

RSD RT [%] |

RSD Area [%] |

|

Benzoic acid |

0.394 |

0.11 |

0.395 |

0.11 |

0.347 |

0.159 |

0.406 |

0.18 |

0.44 |

0.132 |

0.234 |

|

Sorbic acid |

0.428 |

0.08 |

0.287 |

0.08 |

0.377 |

0.245 |

0.35 |

0.125 |

0.427 |

0.093 |

0.312 |

|

Methyl-4-HB |

0.476 |

0.09 |

0.283 |

0.052 |

0.361 |

0.15 |

0.377 |

0.077 |

0.427 |

0.074 |

0.273 |

|

Ethyl-4-HB |

0.544 |

0.046 |

0.304 |

0.037 |

0.375 |

0.071 |

0.358 |

0.043 |

0.429 |

0.044 |

0.568 |

|

Propyl-4-HB |

0.610 |

0.015 |

0.288 |

0.02 |

0.356 |

0.042 |

0.351 |

0.017 |

0.408 |

0.041 |

0.257 |

|

Butyl-4-HB |

0.670 |

0.013 |

0.304 |

0.015 |

0.379 |

0.027 |

0.367 |

0.016 |

0.445 |

0.027 |

0.554 |

|

Butylated Hydroxyanisol |

0.702 |

0.016 |

0.306 |

0.011 |

0.309 |

0.02 |

0.357 |

0.014 |

0.491 |

0.049 |

0.815 |

Table 1. Precision values for the different setups in detail.

Table 1 shows the determined values for relative standard deviations (RDS), calculated for intra-needle precision (Column 1, Needle 1 and Column 1, Needle 2), inter-needle precision (Column 1 and 2, Dual Needle), as well as for the precision in the complete setup (Dual Needle Automated column regeneration). The intra-needle area precision was below 0.4% for both needles, tested with column 1. The inter-needle precision was still excellent with RSDs below 0.45%. Even considering the variation of the complete setup using two different injections and pathways including two needles with two alternating columns, the area precision was excellent with RSDs under 0.57%, except of the last peak with 0.815%. All retention time RSDs were excellent with values below 0.25% for the early eluting analytes and even below 0.08 % for the later eluting analytes.

Enlarge

Enlarge

Figure 3. Time saving for ultra high-throughput over 100 injections.

Using parallel injection of the next sample, as well as the parallel column regeneration, enabled a decrease in the overall cycle time of over 60%. For 100 injections, the time could be decreased from 260 minutes (sequential runs) down to 110 minutes (overhead time not included), see Figure 3. Additional overhead time has to be added to the analysis time for detector balancing, saving data and other software related processes. However, the ratio of the total time saving is not affected when including the overhead time – still resulting in a total time saving of over 60%.

Expansive portfolio of high-performing LC, HPLC, and UHPLC solutions for food analysis

For the analysis of food preservatives, our test results demonstrate savings of over 60% reduction in total analysis time using alternating column regeneration in combination with parallel injection by the second needle. Retention time and especially area precision – both important quality parameters for injectors – was excellent for inter and intra-needle, as well as inter and intra-column analysis. The described setup using the Agilent 1290 Infinity II Multisampler, equipped with a dual-needle option, is well-suited and reliable for the high-throughput analysis for food monitoring experiments. Agilent offers a wide array of Liquid Chromatography, HPLC, and UHPLC solutions that will benefit all of your food analysis needs. Contact your Agilent Representative today to find out more.

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Figure 2.

|

|

High-throughput – ZORBAX RRHD Eclipse Plus C18, 2.1 x 50 mm, 1.8µm |

|---|---|

|

Mobile phase |

A: Water + 20 mM Ammonium Formate, pH 4.4, B: Acetonitrile |

|

Flow rate |

1.5 mL/min |

|

Gradient Pump |

3% B at 0 minutes, 60% B at 0.5 minutes, 80% B at 0.6 minutes, 95% B at 0.65 minutes, 3% B at 0.7 minutes |

|

Equilibrium pump |

3% B at 0 minutes, 95% B at 0.05 minutes, 95% B at 0.2 minutes, 3% B at 0.3 minutes |

|

Stop time both pumps |

1.1 minutes |

|

Needle wash mode |

Standard wash |

|

Injection volume |

1.00 µL |

|

Needle selection |

Alternating needle |

|

Enabled smart overlap |

Yes |

|

Smart overlap wait time |

0.70 min |

|

Column temperature |

40 °C |

|

Detection |

260/40 nm, reference 380/100 nm, Data rate 160 Hz |

Overlay of 14 subsequent runs of the preservatives separation with dual-needle setup and automated column regeneration.