Access Agilent eNewsletter, June 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Efficient and cost-effective analysis of computer disk lubricants with Agilent GPC/SEC

By Yulan Bian

Agilent GPC Applications

Lubrication is an essential and crucial process in the manufacturing operation and performance of computer hard disks. A layer of lubricant coated on the disk surface reduces wear and friction when disk drives operate at high speed. This thin layer of lubricant also protects against corrosion of the underlying magnetic alloy. Reliability of hard disks largely depends on the durability of this thin film and therefore many hard disk manufacturers develop their own proprietary lubricants.

Easily maintain quality control in hard disk manufacturing

Different methods and instruments are used to confirm and control the properties and quality of disk lubricants. Examples include Nuclear Magnetic Resonance (NMR), Fourier Transform Infrared Spectroscopy (FT-IR) and Gel Permeation Chromatography/Size Exclusion Chromatography (GPC/SEC). GPC/SEC separates molecules based on their size in solution, which is related to molecular weight, and is widely used in the quality control of lubricants. If the molecular weight distribution of a batch of lubricant falls out of the desired range, it will fail specification and be rejected for the coating process. In this article, we explore Agilent GPC/SEC solutions for cost-effective analysis of computer disk lubricants.

The lubricant sample in this experiment is a linear molecule with a polar end group at each end of the polymer chain. Each of the individual calibrants and lubricant samples were dissolved in tetrahydrofuran (THF) at an approximate concentration of 1 mg/mL. The concentration accuracy is usually not as critical for conventional GPC analysis – because the calculation of the molecular weight averages and molecular distribution are not dependent on the sample concentration.

Enlarge

Enlarge

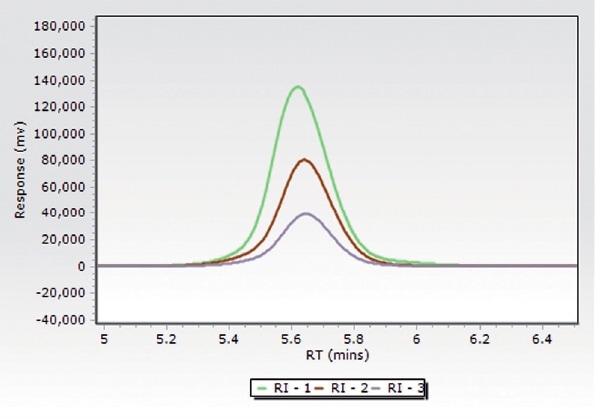

Figure 1. Overlay of chromatograms of three batches of hard disk lubricant.

Enlarge

Enlarge

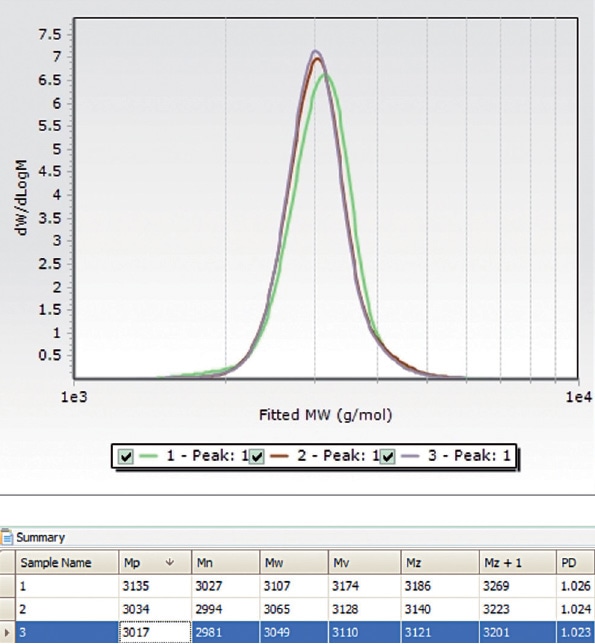

Figure 2. Overlay of molecular weight distribution plots for three batches of hard disk lubricant, and summary table.

Agilent has the right GPC column for your lubricant analysis needs

The average molecular weight (Mw) of the lubricant sample is expected to be around 3,100 g/mol ± 5%, with a polydispersity (PD) of 1.0 to 1.2, against polystyrene narrow standards. For this reason, an Agilent PLgel 3 µm 100Å, 7.5 x 300 mm column was chosen due to its suitable linear operating range (up to 4,000 g/mol) and high efficiency (>100,000 plates/m). The narrow linear range and high efficiency provides excellent resolving power for this low molecular weight, low polydispersity sample. The GPC analysis was performed with an Agilent 1260 Infinity GPC/SEC System using Agilent GPC/SEC software.

Samples from three different batches were analyzed and shown overlaid in Figure 1. Due to the concentration difference between the samples, the peak heights are different. However, this does not affect the molecular weight distribution calculation of the samples, as shown in Figure 2.

Compare and overlay samples with ease and accuracy

The data reviewer window of the Agilent GPC/SEC software allows us to compare and overlay normalized molecular weight distributions of a number of different samples. Figure 2 shows the overlaid molecular weight distribution plots of the three batches of lubricants, together with their molecular weight averages tabulated below. Based on the calculated results, the molecular weight for all three lubricant samples met the required Mw and PD specification for quality control and therefore they are considered as certified for intended use.

This GPC method and instrumentation delivers a critical analytical step in maintaining the quality control processes of the hard disk manufacturing industry. You can read full details of this analysis in Agilent Publication 5991-4321EN.

Agilent GPC/SEC solutions efficiently prove viability, while increasing confidence

As demonstrated, reliable analyses of polymer manufacturing materials are vital to ensure product performance. Due to the importance of efficiency and cost-effectiveness, it is essential to run accurate analytical processes that can quickly ascertain fit-for-purpose. The Agilent GPC/SEC portfolio of columns, standards, instruments, and software delivers the reassurance you need when assessing critical materials. Explore further in the new, handy, and informative GPC wall chart Achieve more with the polymer analysis people. Order your free copy now.

>> Update My Profile | Subscribe to Access Agilent | Article Directory