Access Agilent eNewsletter, August 2014

>> Update My Profile | Subscribe to Access Agilent | Article Directory

The evolving world of non-destructive testing

By John Seelenbinder

Agilent Marketing Manager, Mobile Measurement FTIR Products

According to ASM International, non-destructive testing (NDT) comprises “…a wide range of techniques used to evaluate the properties of a material, component, or system without causing damage.”

Early on, the NDT technique focused on assessment of physical defects or physical conditions, using visual inspection, ultrasonics, dye penetration, radiography, or hardness testing to assess cracks, leaks, bonding failure, and porosity. More recently, measuring elemental and chemical composition has become increasingly important. New materials bring with them new failure mechanisms. Thermal damage, UV exposure, and chemical exposure are causes of chemical damage to advanced materials. Additionally, material identification and qualification is very important due to concerns about counterfeits, contaminants or material specifications arising from worldwide sourcing variables.

Rising to the challenge

New NDT technologies have been developed to meet these challenges. Today, handheld spectroscopy instruments provide advanced capabilities that have revolutionized NDT over the last 15 years. Improvements to electronics, optics, and battery technology now deliver performance previously only available in the laboratory. On-site elemental analysis is now possible, using X-ray fluorescence for metal alloy confirmation. For chemical analysis, FTIR, near-IR, and Raman spectroscopy are excellent for the identification and measurement of chemical degradation. In this article we discuss the use of the Agilent 4300 Handheld FTIR for non-destructive testing.

Non-destructive testing with handheld FTIR

FTIR can be used for two distinct types of non-destructive analysis: identification/classification and damage analysis/surface qualification. Identification is accomplished by a simple library search. A correlation algorithm matches the sample to either a purchased or user created library, ranking the results by R2. Similarly, classification uses discriminant analysis for statistical separation of chemically relevant groups. This turns the analysis into a yes/no question: Is this the correct material? Does this material meet specification? This type of analysis is more sensitive than a library search.

Surface preparation and damage assessment both require a numeric or quantitative measurement. FTIR is also a quantitative technique; the spectral response can be correlated to the extent of either damage or surface preparation through the use of linear or partial least squares algorithms.

Enlarge

Enlarge

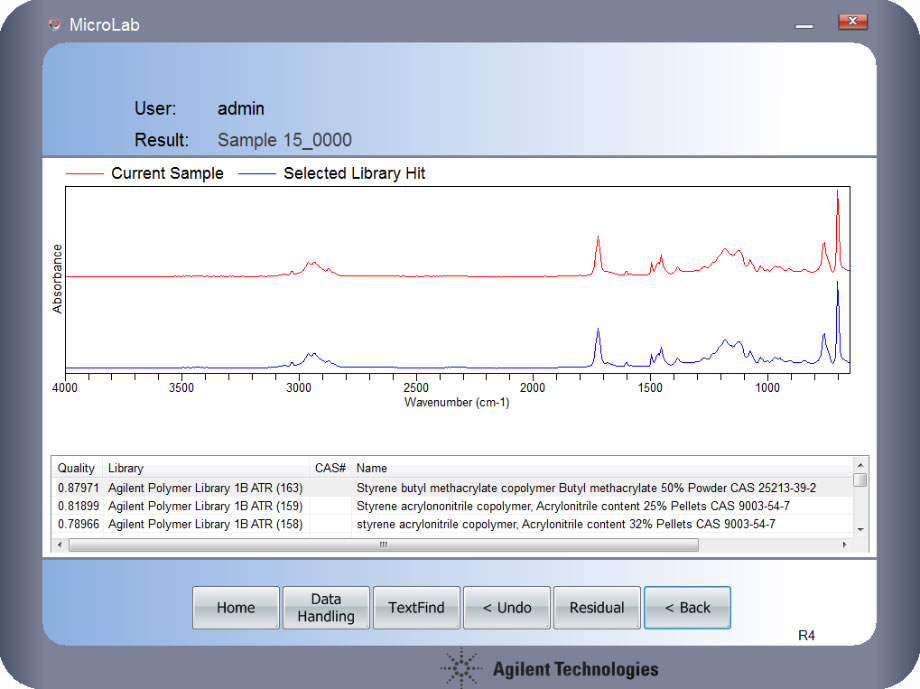

Figure 1. The Agilent 4300 Handheld FTIR identifies components of a polymeric material by comparison with entries in a sample library.

Enlarge

Enlarge

Figure 2. Example of results from use of Agilent 4300 handheld FTIR to classify a polymer.

Handheld FTIR for positive material identification and qualification

The Agilent 4300 Handheld FTIR is easy to use and simple to implement. Often, only a basic identification is required from a large number of materials or possibilities, i.e. “is this nylon or polystyrene?” The 4300 FTIR uses commercially available or self-generated libraries. Handheld measurement using the Agilent Diamond ATR Sample Interface provides library matches with high correlations (> 0.9) with a correct match. One advantage of the library technique is that it can identify material even if it’s not the correct composition.

Figure 1 shows how the Agilent 4300 FTIR identified scrap polymer material sourced from electronics equipment, using Agilent MicroLab software and polymer libraries. The spectrum and identity of the unknown polymer sample is shown, as well as the spectrum of its best library match and a numerical value that reflects the quality of that match.

Sometimes a positive confirmation of the materials’ identity and quality is needed with a high degree of certainty. Fundamentally, this is a different question: “Is this material X… yes or no?” A discriminant analysis answers the yes/no question with a known error, giving greater confidence in the answer. Figure 2 shows a polymer classification using a partial least squared discriminant analysis. Both the cross validation result and the user output of the Agilent Microlab Mobile software are shown.

Taking the lab to the sample

Handheld FTIR comes into its own when articles are too big or too expensive to take to the laboratory. When it comes to aerospace or automotive components, building materials, solar panels, wind turbines, or large composite parts, having the ability to conduct analysis on-site is invaluable. For a detailed discussion of the use of Agilent’s handheld FTIR in the analysis of such materials, refer to Agilent Application Note 5991-4033EN.

Multiple methods for analysis of advanced materials

Agilent’s reliable and robust range of instrumentation and consumables for polymer characterization delivers fast and actionable information about the composition and response of polymers and composites. Our suite of molecular spectroscopy solutions can tackle any analytical challenge, from routine measurements and troubleshooting to cutting edge applications.

Our laboratory FTIR bench and microscopy systems provide insights into characterization of both bulk and detailed structure analysis, as well as for mobile measurements – offering supplies and standards to match. What’s mo. What’s more, the Agilent GPC/SEC portfolio offers market-leading instrumentation, columns, standards, and data analysis software for polymer analysis. Now, take a moment to discover how Agilent’s industry-leading HPLC systems accelerate decision times in batch testing with accurate molecular weight information.

>> Update My Profile | Subscribe to Access Agilent | Article Directory