Access Agilent eNewsletter, November 2013

>> Update My Profile | Subscribe to Access Agilent | Article Directory

Evaluation of mechanical properties of polyethylene based on structural properties measured with the Agilent PL-GPC 220

By Adrian Boborodea

Senior Scientist, Certech ASBL

The pressure for fast development of polyethylenes with well-defined mechanical properties has increased the need for rapid analytical methods to predict these properties using small quantities of material. To meet this need, the Agilent PL-GPC 220 high temperature GPC/SEC system uses three complementary detectors simultaneously, to quickly measure structural properties requiring only small sample quantities. The system operates across a wide temperature range – from ambient to 220 °C to cover all GPC applications.

The development of new commercially useful single-site catalysts for olefin polymerization requires multiple polymerizations on a small scale. This initial screening process can include more than 1500 polymerizations, each on a 20 mL scale, to produce between 50 and 500 mg per sample. These quantities are not sufficient for a complete evaluation of mechanical properties by all available techniques, so selection of the most appropriate technique for the initial screening is critical.

The evaluation of macroscopic properties (density, melt flow index, impact) based on structural parameters (melting temperature, molecular weight distribution, IR spectrum) measured with classical techniques (differential scanning calorimetry, FT-IR, gel permeation chromatography, rheology, dynamic mechanical analysis) follows in the next stage. This evaluation is both time-intensive and requires larger quantities of material.

Simple, fast method to predict properties

Gel permeation chromatography/size exclusion chromatography (GPC/SEC) requires a relatively low sample quantity, and through the use of advanced detectors can provide information to determine key parameters. In Agilent Application Note 5991-2781EN, evaluation of polyethylene type, the goal was to decrease the quantity of synthesized material that you need to predict several mechanical properties, while decreasing the overall time required.

Enlarge

Enlarge

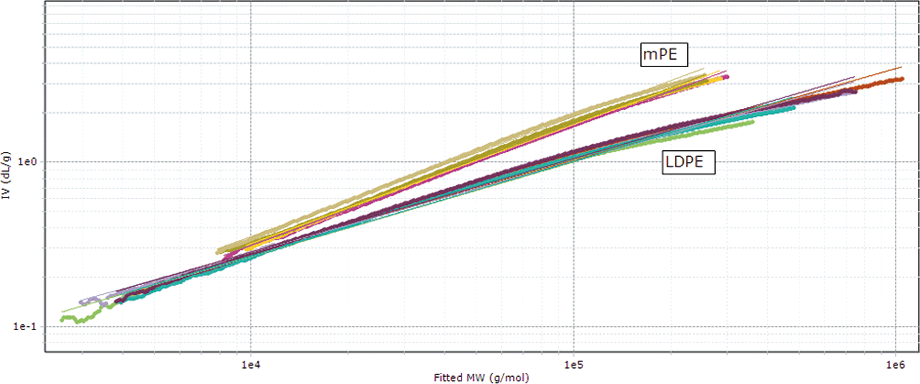

Figure 1. Overlay of Mark-Houwink plots for polyolefin sample highlights the difference between linear and low-density polyethylene.

The correlation between density and mechanical properties strongly depends on the type of polyethylene, which you can determine using GPC with triple detection. Figure 1 shows some results from Application Note 5991-2781EN, which describes polyethylene analyses performed by Certech, an Agilent Authorized Partner Laboratory [1].

Predict properties with initial screen of less than 10 mg material

Use of GPC with triple detection allows you to reduce the necessary quantity of material to less than 10 mg, so you can predict many mechanical properties during the first screening. In addition, you get a better measurement of the absolute molecular weight for the correct evaluation of melt flow index (MFI). This method allows you to establish the type of polyethylene, which is the first step to apply the equations to evaluate the mechanical properties based on structural properties.

Even better, because you can largely automate the experiment once sample preparation has been completed, you save significantly in both laboratory labor hours and use of laboratory facilities. For example, while you can use a rotational rheometer to evaluate MFI, you need about 100 times more material than with GPC. The rotational rheometer provides no information about the molecular weight distribution, for example whether the sample is monomodal or bimodal, and you must manually introduce each sample. The actual GPC/SEC experiment is twice as quick to perform, but the working hours saved is fourfold, equating to 800 person-hours in this study of 1600 samples. In practice, only 200 to 300 samples out of the 1600 produced would actually have been analyzed without triple detection GPC, because the time/costs would have been too prohibitive.

Enlarge

Enlarge

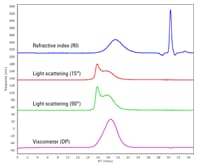

Figure 2. Chromatogram shows all traces on the PLgel Mixed-B column set: refractive index, light scattering (15° and 90°) and viscometer differential pressure (DP).

Triple detection delivers more thorough sample characterization

As shown in Figure 2, triple detection GPC consists of a refractive index (RI) detector, a viscometer, and a light scattering detector.

Each of the three detectors provides key information. A refractive index (RI) detector responds to the polyolefin concentration independent of the molecular weight or polyolefin structure. The RI detector is the industry standard for numerous reasons, and therefore is essential in this type of study. Other benefits arise because you can back-calculate the injected mass of the sample based on the peak area, which allows you to verify the percentage of the polymer in the injected sample. The percentage is extremely important in assessment of the activity of the catalyst.

A viscometer calculates the intrinsic viscosity across the molecular weight distribution. You use this information to create a Mark-Houwink plot, which can help to predict the shape of the polymer in solution and to determine long-chain branching within the polyolefin using branching models in the Agilent GPC/SEC Software.

A light scattering detector provides molecular weights from first principles, which ensures accurate values and negates the requirement for a column calibration. For large polyolefins (greater than about 10 nm), you can also employ this detector for branching.

Figure 3. Agilent PL-GPC 220 high temperature GPC/SEC system features the widest commercially available application range.

Increase certainly with triple analysis across a wide temperature range

The Agilent PL-GPC 220, shown in Figure 3, houses all these detectors within the same oven, which you can heat to 220 °C to prevent polyolefin precipitation. The Agilent PL-GPC 220 is the only commercially available instrument to provide RI-based triple analysis across such a temperature range, which ensures a high level of confidence.

Triple detection high temperature GPC/SEC provides critical information and saves time and money in the evaluation of polyolefins.

Explore Agilent’s polymer solutions

Do you have a tough analytical problem to solve? Then it is time to explore the new Agilent GPC application portfolio where you will find many more polymer applications, together with advice on selecting the right system for your application.

Reference

- Agilent has engaged in collaboration with Certech – a contract research organization, active in the field of environment, materials technology, process intensification, and providing support to the industries. Activities include analysis and measurements, problem-solving, contract research, product, and process development capabilities.

>> Update My Profile | Subscribe to Access Agilent | Article Directory