Throughout the response to the COVID-19 pandemic, clinicians and researchers have faced daunting questions of how to scale testing in order to meet the demand. Research laboratories that may have been accustomed to processing a few handfuls of samples a day are now being asked to process thousands as they seek solutions to this crisis.

This need for higher sample throughput applies both to the nucleic acid–based test used for initial COVID-19 research as well as antibody research that help assess whether a person has been exposed to the virus and have been able to mount an immune response.

While both types of tests are critical, the need for antibody testing is expected to increase as researchers attempt to answer questions such as: How much of the population has been exposed to the virus SARS-CoV-2? How close are we to achieving herd immunity? Which candidate vaccines are showing efficacy?

In this post, we will examine what can be done to help scale antibody testing research.

Laboratory work meets logistics

To determine if a particular type of antibody is present in a person's serum, it is common to analyze a blood sample from that individual using a laboratory test known as an ELISA (enzyme-linked immunosorbent assay). Please see our recent post detailing the mechanics of ELISA.

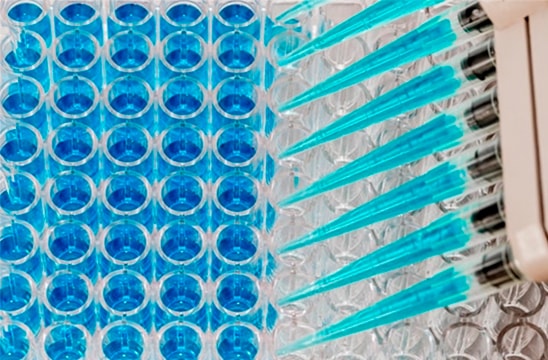

In practice, ELISAs are performed in a specialized vessel known as a microplate. In the same way shipping containers are effective for moving large quantities of goods around the world efficiently, microplates serve as a platform for processing large numbers of samples in a laboratory. The typical microplate used for ELISAs has 96 separate wells, meaning dozens of samples, along with necessary experimental controls, can be processed in a container about the size of a mobile phone.

While this ability to run multiple samples in parallel greatly contributes to the efficiency of research of ELISA for performing antibody tests, performing an ELISA remains a multi-step process. An ELISA is carried out in a sequential process involving the addition of different reagents, washes to remove unbound antibody, and culminating in measurement of the reaction signal using a spectrophotometer. While handling dozens of samples in a microplate offers many benefits, the challenge presented by COVID-19 research is the ability to process dozens and dozens of microplates.

The hardware behind the labware

What ultimately allowed the shipping container to revolutionize global commerce was not the box itself, but rather its standardized size, which enabled the development of an underlying infrastructure to facilitate its movement through logistics networks. Similarly, the advent of the microplate has led to the development of laboratory instruments specifically designed to process samples in this format.

BioTek Instruments (now a part of Agilent) designs and produces specialized equipment for dispensing and aspirating liquids to and from microplates, and detection devices such as spectrophotometers configured to measure samples arrayed in microplates. Since many of the steps involved in the ELISA process are repetitive and laborious, equipment from BioTek Instruments helps in automating ELISA research workflows.

While instruments such as those from BioTek are capable of performing specific operations on microplates, there is still a need for "hands" to serve the microplates to these instruments. Here the infrastructure of laboratory automation extends to robots such as the Agilent BenchCel, which are designed for handling microplates.

Creating an automated ELISA platform

With the extent of the COVID-19 pandemic rapidly emerging and the consequential need for increased antibody research, specifically using ELISA, becoming readily apparent, colleagues across Agilent Automation and BioTek saw the potential of integrating these instruments . A system comprising a BenchCel microplate handler, positioned between a BioTek liquid handling and plate reader, would provide a compact benchtop solution capable of automating nearly all the steps of the ELISA workflow and providing the ability to process thousands of research samples a day.

To create an automated ELISA platform that would be a viable solution for large research laboratories, the teams set to work developing the necessary software and hardware to allow the individual instruments to come together as one system. The teams worked together even while they remained physically separated — not simply on opposite coasts, but due to social distancing also sequestered in home offices and basements, whether in the normally bustling Bay Area or typically quiet Vermont towns.

Within two months of kicking off the effort, the teams completed the necessary development work to enable the system integration and expect to be able to ship equipment to labs performing COVID-19 antibody research within a matter of weeks.